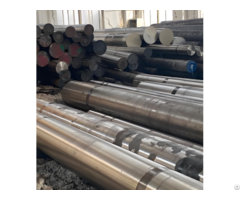

Rolling Bearing Isc B00150 Steel Lf Refining Process - China

price: 157.00 Dollar US$

ISC B00150 steel is a low-carbon steel.

The LF refining process aims to improve its purity and precisely control its composition and temperature.

The following are the main steps and key points of the LF refining process for ISC B00150 steel in general:

1 - Pre-refining Preparation: Carefully inspect the operating status of all LF furnace systems, including electrodes, argon gas, and furnace cover.

Also, verify whether the accident pit is free of water and that raw materials, tools, and alloy silos are in normal condition.

2 - Tapping and Preliminary Treatment: During tapping, ensure proper slag control and limit the amount of slag released to no more than 5 kg/t to prevent excessive oxidizing slag from entering the ladle and impacting subsequent refining.

After the ladle receives the molten steel, the ladle car is moved to the refining station, and argon gas is connected for purging.

Simultaneously, lime, fluorite, composite deoxidizers, aluminum granules, and other materials are added for rapid slag formation.

3 - Arc Heating and Slag Optimization: An electrode is lowered and inserted into the slag, and the arc is used to heat the molten steel.

To reduce heat loss and erosion of the furnace lining, ISC B00150 steel is generally heated using submerged arc heating.

During the heating process, the argon flow rate, current level, and slag viscosity are adjusted according to the smelting progress and slag conditions.

Slag formation is usually based on the white slag method.

The slag basicity R ≥ 4 is controlled, and the w(TFe+MnO) content in the slag is ≤ 1.0%, forming a slag system mainly composed of CaO-Al₂O₃-SiO₂.

Songshun Steel

What We Provide

Our main products are round and flat bars for alloy steel, tool steel, stainless steel, spring steel, bearing steel and etc.

In those years we offers a wide range of high quality steel for engineering machinery, mold tooling, cutting tools manufacturing industry and etc.

Songshun Company Website:

https: //songshunsteel.

com/

songshunsteel20240115

Company Contact:

- Posted By: Dongguan Songshun Mould Steel Co., Ltd.

- Phone: 076985475596

- Address: 1st Floor, No. 1, Dongda Fourth Street, Shatou Community, Chang'an Town, Dongguan , Guangdong , China

- Email:

- Website: https://songshunsteel.com/

Published date: September 15, 2025

- Business Description: Established in 2009,Songshun Steel supplies a wide range of carbon, alloy and tool steel products, including high speed tool steel, cold work tool steel, hot work tool steel, plastic mould steel, engineering steel and machine structural steel etc.

After more than 10 years development and growing, Songshun Steel becomes one comprehensive special steel factory, stockist and exporter.

Combined with experienced exporting team and professional technical knowledge, Songshun Steel offers both technical advice and support, as well as global professional steel solution and service.

Due to satisfactory reliable quality and professional service, Songshun expands our market worldwide, such as Colombia, Chile, Spain, Turkey, Iran, Vietnam, Malaysia ,UAE, Canada, Brazil, Mexico and so on.

Songshun specialized in Special Steel for almost 20 years.

We can supply mold steel, high speed steel, alloy steel, free cutting steel and etc.

Welcome your contact 24 hours a day!!!

Skype/Whatsapp/We chat: +86-18269260283

Songshun Tiktok: mikizhuo

Songshun Facebook: Songshun Steel

Songshun YouTube: MiKi Zhuo

songshunmoldsteel414 04340

Related listings

-

High Chromium Bearing Steel Gcr15 Material Manufacturing MethodMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - September 15, 2025 - 155.00 Dollar US$

High Chromium Bearing Steel Gcr15 Material Manufacturing MethodMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - September 15, 2025 - 155.00 Dollar US$GCr15 material is the most commonly used high-chromium bearing steel. It has high hardenability and can achieve high and uniform hardness after heat treatment. It has better wear resistance than GCr9, high contact fatigue strength, good dimensional s...

-

High Quality Steel Gcr15 Rich Spot Resources Adequate SupplyMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - September 15, 2025 - 154.00 Dollar US$

High Quality Steel Gcr15 Rich Spot Resources Adequate SupplyMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - September 15, 2025 - 154.00 Dollar US$Steel GCr15 is a high-carbon chromium bearing steel with a carbon content of 0.95%-1.05% and a chromium content of 1.40%-1.65%. It exhibits high hardenability, wear resistance, and contact fatigue strength, making it widely used in bearing manufactur...

-

Gb Gcr15 Material Various Annealing ProcessesMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - September 15, 2025 - 151.00 Dollar US$

Gb Gcr15 Material Various Annealing ProcessesMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - September 15, 2025 - 151.00 Dollar US$1. Incomplete Annealing: Heat GB GCr15 material to 770-790°C, hold, and then cool to below 550°C in the furnace. Remove from the furnace and air cool. Hardness requirement: 187-229 HBS. Process characteristics: Ac1 = 745°C, Accm = 900°C. Heating temp...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"