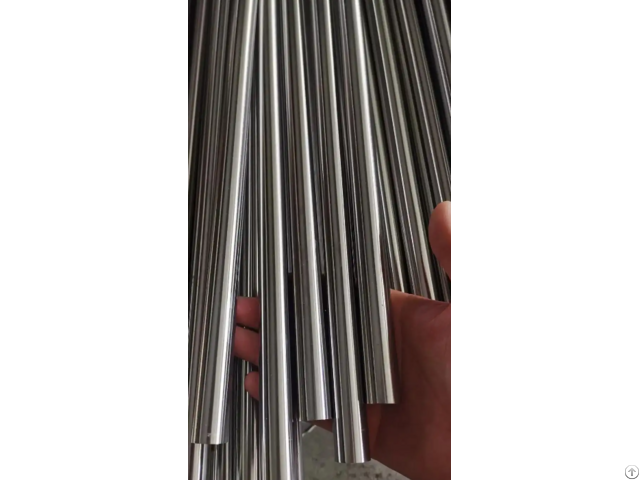

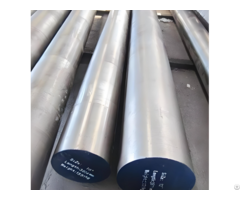

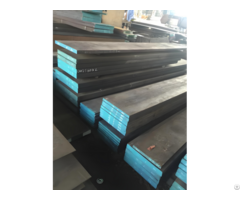

High Quality 1 2363 Material Exhibits Minimal Deformation During Heat Treatment - China

price: 103.00 Dollar US$

1.2363 material, as a high-carbon, medium-chromium cold work die steel, exhibits minimal deformation during heat treatment primarily due to its compositional design, microstructure, and suitable processing techniques, meeting the dimensional stability requirements of precision molds.

Key Reasons for Minimal Deformation: 1 - Synergistic Compositional Control of Phase Transformation: High carbon (approximately 1.0%) ensures hardness and wear resistance; 5% chromium enhances hardenability and carbide stability; molybdenum and vanadium refine grains and inhibit austenite grain coarsening, reducing phase transformation volume differences and microstructural stress.

2 - Uniform Microstructure and Refined Grain: Inclusions are controlled during smelting and forging, resulting in a uniform pearlite + carbide microstructure after annealing; vanadium carbides hinder austenite growth, leading to a fine and uniform martensite microstructure after quenching, making deformation more controllable.

3 - Excellent Hardenability and Cooling Suitability: It can be air-quenched/pressurized gas-quenched/staged oil-quenched, avoiding the severe thermal stress of water cooling; even large cross-sections can achieve uniform hardening, reducing deformation caused by asynchronous internal and external temperature differences and microstructural transformation.

Material 1.2363 achieves low deformation during heat treatment through the synergy of its composition, structure, and processing, making it a preferred material for precision cold-working dies.

songshunsteel20260115

Company Contact:

- Posted By: Dongguan Songshun Mould Steel Co., Ltd.

- Phone: 076985475596

- Address: 1st Floor, No. 1, Dongda Fourth Street, Shatou Community, Chang'an Town, Dongguan , Guangdong , China

- Email:

- Website: https://songshunsteel.com/

Published date: January 26, 2026

- Business Description: Established in 2009,Songshun Steel supplies a wide range of carbon, alloy and tool steel products, including high speed tool steel, cold work tool steel, hot work tool steel, plastic mould steel, engineering steel and machine structural steel etc.

After more than 10 years development and growing, Songshun Steel becomes one comprehensive special steel factory, stockist and exporter.

Combined with experienced exporting team and professional technical knowledge, Songshun Steel offers both technical advice and support, as well as global professional steel solution and service.

Due to satisfactory reliable quality and professional service, Songshun expands our market worldwide, such as Colombia, Chile, Spain, Turkey, Iran, Vietnam, Malaysia ,UAE, Canada, Brazil, Mexico and so on.

Songshun specialized in Special Steel for almost 20 years.

We can supply mold steel, high speed steel, alloy steel, free cutting steel and etc.

Welcome your contact 24 hours a day!!!

Skype/Whatsapp/We chat: +86-18269260283

Songshun Tiktok: mikizhuo

Songshun Facebook: Songshun Steel

Songshun YouTube: MiKi Zhuo

songshunmoldsteel414 04340

Related listings

-

Din 1 2363 Mold Steel Key Influencing Factors And Control PointsMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - January 26, 2026 - 102.00 Dollar US$

Din 1 2363 Mold Steel Key Influencing Factors And Control PointsMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - January 26, 2026 - 102.00 Dollar US$Key Influencing Factors and Control Points for DIN 1.2363 Mold Steel Quenching Process: Heating rate, holding time, and cooling method determine thermal stress and microstructure transformation. Step heating (e.g., 650℃/850℃ dual-stage), air cooling ...

-

Stock 1 2363 Steel Suggestions For Process OptimizationMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - January 26, 2026 - 101.00 Dollar US$

Stock 1 2363 Steel Suggestions For Process OptimizationMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - January 26, 2026 - 101.00 Dollar US$1.2363 Steel Process Optimization Recommendations Preheating and Quenching: Two-stage preheating at 650℃/850℃, austenitization at 940–960℃, holding coefficient 1.5–2 min/mm, air cooling to room temperature followed by immediate tempering. Tempering C...

-

W Nr 1 2363 Steel Processing And Manufacturing ConsiderationsMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - January 26, 2026 - 100.00 Dollar US$

W Nr 1 2363 Steel Processing And Manufacturing ConsiderationsMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - January 26, 2026 - 100.00 Dollar US$In design and manufacturing, W-Nr.1.2363 steel must be combined with optimized heat treatment processes, precision grinding, and rigorous testing to fully realize its potential and produce high-end gears with ultra-long service life and reliable perf...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"