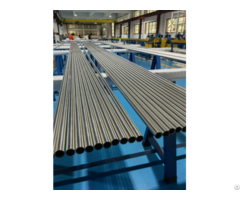

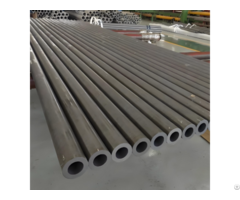

Wear Resistant Titanium Carbide Rods Extended Service Life - China

price: 12.80 Dollar US$

The length of this round bar can be customized according to requirements, ranging from 100mm to 1000mm, and it can undergo secondary processing such as precision grinding and wire cutting to produce parts of various complex shapes.

Although its price is higher than that of ordinary cemented carbide, after considering its service life and processing efficiency comprehensively, the cost per unit product is actually lower.

In the gear processing industry, the hobs made from it can ensure that the gear tooth surface accuracy reaches grade 6 or above, meeting the demands of high-end mechanical transmission.

The production process of this round bar is extremely strict, from the purity control of titanium carbide powder (purity ≥99.5%) to the precise regulation of sintering temperature (about 1500℃), every step affects the final performance.

The finished product features excellent dimensional stability.

Under temperature variations ranging from -50℃ to 300℃, its coefficient of thermal expansion is only 6×10⁻⁶/℃, which is significantly lower than that of metal materials, ensuring the precision of precision tools in various environments.

It is widely used as wear-resistant inserts in automotive molds, capable of withstanding long-term high-pressure friction without easy wear, thus extending the service life of the molds.

Company Contact:

- Posted By: Zhuzhou Hastion High-Tech Materials Co.,Ltd.

- Phone: +86-731-22891182

- Address: Small And Medium-Sized Enterprises Pioneer Park, Yanling County, Zhuzhou City,Hunan Province, China, Zhuzhou , Hunan , China

- Email:

- Website: https://www.hastion.com/

Published date: November 17, 2025

- Business Description: Our factory is in yanling, Zhuzhou of Carbide centralized place,which occupies an area of 60,000 square meters and a planned factory area of 50,000 square meters.

Now HASTION have 2 different

productions lines, one is the raw material metal compound and elemental powder(TiC/Cr3C2/VC/NbC/Z rC/HfC/(W,Ti)C/(Ta,Nb)C and so on), the other one is

the titanium carbide cermet rod/insert/plate/customiz ed shape/guide roller and so on(belong to the steel-bonded cemented carbide), until now our products have been sold to many countries, like the Turkey, Belgium, Australia, Japan, Korea, Vietnam, India, Pakistan, Thailand and etc.

Related listings

-

Iso 20nicrmo2 Alloy Pipe Hardening And Tempering ProcessAlloys - Dongguan Songshun Mould Steel Co., Ltd. - China - November 17, 2025 - 493.00 Dollar US$

Iso 20nicrmo2 Alloy Pipe Hardening And Tempering ProcessAlloys - Dongguan Songshun Mould Steel Co., Ltd. - China - November 17, 2025 - 493.00 Dollar US$Hardening: The hardening of ISO 20NiCrMo2 alloy pipe is completed by oil quenching at 1675F. Carburizing is done in the same 1650F-1700F range within the carburizing range, either "wrapped" or in an ambient environment. Thin profiles are then oil-que...

-

Hot Sale Uns G86200 Alloy Steel With High Strength And ToughnessAlloys - Dongguan Songshun Mould Steel Co., Ltd. - China - November 17, 2025 - 513.00 Dollar US$

Hot Sale Uns G86200 Alloy Steel With High Strength And ToughnessAlloys - Dongguan Songshun Mould Steel Co., Ltd. - China - November 17, 2025 - 513.00 Dollar US$UNS G86200 alloy steel stands out among numerous materials for its outstanding combination of high strength and high toughness. When faced with high loads, it performs with incredible strength, like a powerful giant. In the automotive industry, criti...

-

Heat Treatment Process For Nickel Chromium Molybdenum Astm 8620 Alloy MaterialAlloys - Dongguan Songshun Mould Steel Co., Ltd. - China - November 17, 2025 - 505.00 Dollar US$

Heat Treatment Process For Nickel Chromium Molybdenum Astm 8620 Alloy MaterialAlloys - Dongguan Songshun Mould Steel Co., Ltd. - China - November 17, 2025 - 505.00 Dollar US$Heat Treatment Process 1. Carburizing and Quenching Purpose: To form a high-carbon layer (0.8-1.2mm) on the surface of ASTM 8620 alloy material, obtaining high-hardness martensite after quenching. Process Parameters: Carburizing Temperature: 900-950℃...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"