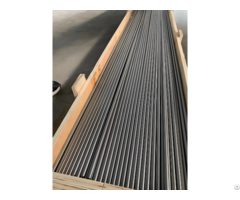

Uns G51300 Steel Forging Process Optimization Solution - China

price: 325.00 Dollar US$

UNS G51300 steel (AISI 5130), a chromium alloy structural steel, excels in the automotive, mechanical, and aerospace sectors for its excellent hardenability, moderate strength, and good toughness.

UNS G51300 Steel Forging Process

The UNS G51300 forging process is designed to optimize the microstructure and reduce segregation and inclusions.

A typical process includes:

1 - Raw Material Preparation and Heating

Raw material: Select high-purity steel ingots or continuous casting billets to ensure uniform chemical composition.

Heating: Heating at 1100-1250°C (approximately 2000-2300°F) is controlled within 1-2 hours per 100mm thickness, depending on billet size, to avoid overheating and grain coarsening.

2 - Forging Deformation

Start forging temperature: 1200-1250°C to ensure good material plasticity.

Final forging temperature: No less than 850-900°C to prevent cracking caused by low-temperature forging.

Deformation rate: Controlled within 20-50% per pass, using multi-pass forging (such as open forging or die forging), with a total deformation ratio of ≥ 3: 1 to achieve grain refinement.

Process Type: Applicable to both open forging (open forging) and closed forging (die forging), with the latter being more suitable for complex shapes.

Forging Process Optimization Solutions: From Simulation to Parameter Control

To improve the quality and efficiency of UNS G51300 steel, optimization solutions focus on defect prevention, performance enhancement, and cost control.

The following are key dimensions:

1 - Temperature and strain rate optimization

2 - Integration of microstructure control and heat treatment

3 - Defect prevention and simulation technology

4 - Cost and environmental optimization Conclusion: UNS G51300 Forging Optimization: Ushering in an Era of High Performance

Forging process optimization for UNS G51300 steel is not only a technological upgrade, but also a revolution in industrial efficiency.

By combining FEM simulation, parameter control, and heat treatment, you can easily achieve a leap in material performance.

Are you ready to apply these solutions to drive project upgrades? UNS G51300 steel is supporting more high-strength applications with its balanced performance!

Company Contact:

- Posted By: Dongguan Songshun Mould Steel Co., Ltd.

- Phone: 076985475596

- Address: 1st Floor, No. 1, Dongda Fourth Street, Shatou Community, Chang'an Town, Dongguan , Guangdong , China

- Email:

- Website: https://songshunsteel.com/

Published date: August 14, 2025

- Business Description: Established in 2009,Songshun Steel supplies a wide range of carbon, alloy and tool steel products, including high speed tool steel, cold work tool steel, hot work tool steel, plastic mould steel, engineering steel and machine structural steel etc.

After more than 10 years development and growing, Songshun Steel becomes one comprehensive special steel factory, stockist and exporter.

Combined with experienced exporting team and professional technical knowledge, Songshun Steel offers both technical advice and support, as well as global professional steel solution and service.

Due to satisfactory reliable quality and professional service, Songshun expands our market worldwide, such as Colombia, Chile, Spain, Turkey, Iran, Vietnam, Malaysia ,UAE, Canada, Brazil, Mexico and so on.

Songshun specialized in Special Steel for almost 20 years.

We can supply mold steel, high speed steel, alloy steel, free cutting steel and etc.

Welcome your contact 24 hours a day!!!

Skype/Whatsapp/We chat: +86-18269260283

Songshun Tiktok: mikizhuo

Songshun Facebook: Songshun Steel

Songshun YouTube: MiKi Zhuo

songshunmoldsteel414 04340

Related listings

-

Customized Various Sizes Din 28cr4 Steel Automotive Parts ManufacturingMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - August 14, 2025 - 323.00 Dollar US$

Customized Various Sizes Din 28cr4 Steel Automotive Parts ManufacturingMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - August 14, 2025 - 323.00 Dollar US$DIN 28Cr4 steel is an alloy structural steel primarily used in the manufacture of high-strength components, particularly in the automotive industry. Its composition and properties make it suitable for withstanding high loads and harsh operating envir...

-

En Nf 32c4 Material Excellent Wear And Impact ResistanceMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - August 14, 2025 - 321.00 Dollar US$

En Nf 32c4 Material Excellent Wear And Impact ResistanceMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - August 14, 2025 - 321.00 Dollar US$EN NF 32C4 material (abbreviated as 32C4), a high-strength structural alloy steel, is widely recognized in the industrial sector for its excellent wear and impact resistance. High strength: Yield strength (Rp0.2) ≥ 700 MPa, tensile strength (Rm) 900-...

-

Custom Processing Of Nf 32c4 Steel Hot Rolling ProcessMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - August 14, 2025 - 320.00 Dollar US$

Custom Processing Of Nf 32c4 Steel Hot Rolling ProcessMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - August 14, 2025 - 320.00 Dollar US$NF 32C4 steel is a low-alloy structural steel with high strength and toughness, making it suitable for manufacturing high-stress fasteners and structural components. Its hot rolling process optimizes the microstructure through high-temperature deform...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"