Uns G43400 Steel Cold Drawing Process Key Steps - China

price: 403.00 Dollar US$

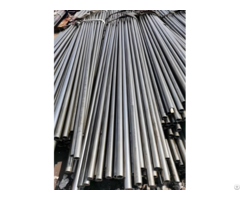

Key steps of cold drawing process of UNS G43400 steel 1 - Raw material preparation

Select SNCM439 steel billet that meets KS standard to ensure that the chemical composition (mainly C: 0.17-0.23%, Cr: 0.60-1.00%, Ni: 0.40-0.70%, Mo: 0.15-0.30%) meets the standard to avoid the cold drawing performance affected by the composition deviation.

Pre-treat the UNS G43400 steel billet: remove surface oil and rust, and perform spheroidizing annealing (reduce hardness and improve plasticity) when necessary to reduce mold wear and avoid steel breakage during cold drawing.

2 - Mold design and selection

Design the mold hole type according to the size of the final product (such as diameter and cross-sectional shape).

The mold material needs to be high-strength alloy tool steel (such as Cr12MoV) and heat treated to improve wear resistance and service life.

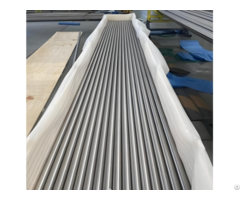

3 - Cold drawing process control

Pulling force calculation: Calculate the required pulling force according to the original size of the steel, the target size and the yield strength of the material to avoid excessive pulling force causing steel breakage or mold damage.

Pulling speed: Generally controlled at 5-15m/min.

Too fast speed can easily cause the steel to heat up and cause surface oxidation or mold overheating, while too slow speed will affect production efficiency.

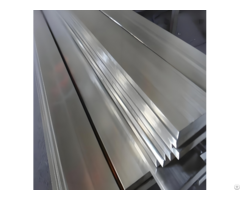

4 - Finished product processing

UNS G43400 steel after cold drawing needs to be straightened to ensure that the straightness meets the requirements.

Remove the residual lubricant on the surface and perform surface anti-rust treatment (such as galvanizing and oiling) if necessary.

Perform dimensional inspection (such as diameter tolerance, ovality) and mechanical property tests (such as hardness and tensile strength) on the finished product to ensure that it meets the design standards.

Songshun Steel Manufacturing

With 7000 tons of hydraulic forging press, electric slag furnace and other high-end production equipment, we produce a great variety of steels with the best quality in China.

Songshun Company Website:

https: //songshunsteel.

com/

songshunsteel20240115

Company Contact:

- Posted By: Dongguan Songshun Mould Steel Co., Ltd.

- Phone: 076985475596

- Address: 1st Floor, No. 1, Dongda Fourth Street, Shatou Community, Chang'an Town, Dongguan , Guangdong , China

- Email:

- Website: https://songshunsteel.com/

Published date: July 14, 2025

- Business Description: Established in 2009,Songshun Steel supplies a wide range of carbon, alloy and tool steel products, including high speed tool steel, cold work tool steel, hot work tool steel, plastic mould steel, engineering steel and machine structural steel etc.

After more than 10 years development and growing, Songshun Steel becomes one comprehensive special steel factory, stockist and exporter.

Combined with experienced exporting team and professional technical knowledge, Songshun Steel offers both technical advice and support, as well as global professional steel solution and service.

Due to satisfactory reliable quality and professional service, Songshun expands our market worldwide, such as Colombia, Chile, Spain, Turkey, Iran, Vietnam, Malaysia ,UAE, Canada, Brazil, Mexico and so on.

Songshun specialized in Special Steel for almost 20 years.

We can supply mold steel, high speed steel, alloy steel, free cutting steel and etc.

Welcome your contact 24 hours a day!!!

Skype/Whatsapp/We chat: +86-18269260283

Songshun Tiktok: mikizhuo

Songshun Facebook: Songshun Steel

Songshun YouTube: MiKi Zhuo

songshunmoldsteel414 04340

Related listings

-

High Toughness Astm 4340 Steel Pipes Stockists SupplyMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - July 14, 2025 - 402.00 Dollar US$

High Toughness Astm 4340 Steel Pipes Stockists SupplyMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - July 14, 2025 - 402.00 Dollar US$ASTM 4340 steel pipes are a type of high-strength, high-toughness low-alloy steel widely used in aerospace, petroleum industry, military and other fields. When made into steel pipes, their high toughness and strength characteristics make them particu...

-

Ks Sncm439 Bars Special Hardness Enhancement ProcessMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - July 14, 2025 - 401.00 Dollar US$

Ks Sncm439 Bars Special Hardness Enhancement ProcessMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - July 14, 2025 - 401.00 Dollar US$To further improve the hardness of KS SNCM439 (equivalent to JIS SNCM439, equivalent to SAE 4340) rods, in addition to standard quenching and tempering heat treatment (quenching + tempering), the following special hardness improvement processes can b...

-

Direct Supply Of Ks Sncm439 Steel Cold Drawing ProcessMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - July 14, 2025 - 400.00 Dollar US$

Direct Supply Of Ks Sncm439 Steel Cold Drawing ProcessMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - July 14, 2025 - 400.00 Dollar US$KS SNCM439 steel is an alloy structural steel in the Korean standard (KS), corresponding to my country's 20CrNiMo steel. It has good hardenability, strength and toughness, and is often used to manufacture important parts that withstand impact loads. ...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"