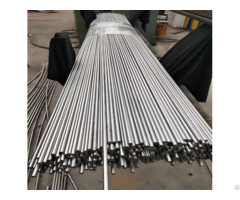

Spot Supply 41cr4 Steel Surface Nitriding Treatment - China

price: 708.00 Dollar US$

41Cr4 steel is a typical alloy structural steel, which belongs to nitridable steel.

The alloy elements it contains (such as chromium Cr) are conducive to nitriding treatment.

Surface nitriding treatment of 41Cr4 steel can significantly improve its surface hardness and wear resistance, while maintaining good toughness and strength of the core, which is suitable for manufacturing mechanical parts with high surface hardness and wear resistance.

Characteristics of surface nitriding treatment of 41Cr4 steel

Nitriding hardness: 41Cr4 steel is nitrided after quenching and tempering, and the surface hardness can reach 72~78HRA, and the core hardness is maintained between 43~55HRC.

This hardness combination makes the surface of the part extremely wear-resistant and the core toughness is good.

Nitriding process route: The typical process flow is forging-annealing-rough machining-quenching and tempering (tempering)-finishing-str ess relief-rough grinding-nitriding-fine grinding or grinding.

Because the nitrided layer is thin and brittle, it must first be tempered heat treated to obtain tempered troostite structure to improve the mechanical properties of the core and the quality of the nitrided layer.

Nitriding process temperature: Nitriding is usually carried out in the range of 500~580℃, and the time ranges from several hours to dozens of hours (adjusted according to the specific process requirements).

Nitrogen diffuses into the steel surface to form hard nitrides, mainly including iron nitrides and alloy element nitrides (such as CrN), which significantly improve the surface hardness and fatigue resistance.

Company Contact:

- Posted By: Dongguan Songshun Mould Steel Co., Ltd.

- Phone: 076985475596

- Address: 1st Floor, No. 1, Dongda Fourth Street, Shatou Community, Chang'an Town, Dongguan , Guangdong , China

- Email:

- Website: https://songshunsteel.com/

Published date: April 28, 2025

- Business Description: Established in 2009,Songshun Steel supplies a wide range of carbon, alloy and tool steel products, including high speed tool steel, cold work tool steel, hot work tool steel, plastic mould steel, engineering steel and machine structural steel etc.

After more than 10 years development and growing, Songshun Steel becomes one comprehensive special steel factory, stockist and exporter.

Combined with experienced exporting team and professional technical knowledge, Songshun Steel offers both technical advice and support, as well as global professional steel solution and service.

Due to satisfactory reliable quality and professional service, Songshun expands our market worldwide, such as Colombia, Chile, Spain, Turkey, Iran, Vietnam, Malaysia ,UAE, Canada, Brazil, Mexico and so on.

Songshun specialized in Special Steel for almost 20 years.

We can supply mold steel, high speed steel, alloy steel, free cutting steel and etc.

Welcome your contact 24 hours a day!!!

Skype/Whatsapp/We chat: +86-18269260283

Songshun Tiktok: mikizhuo

Songshun Facebook: Songshun Steel

Songshun YouTube: MiKi Zhuo

songshunmoldsteel414 04340

Related listings

-

Vacuum Degassing Process 40cr Materials Uniform Metallographic StructureMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - April 28, 2025 - 707.00 Dollar US$

Vacuum Degassing Process 40cr Materials Uniform Metallographic StructureMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - April 28, 2025 - 707.00 Dollar US$The vacuum degassing process plays a key role in the production and heat treatment of 40Cr materials. It is mainly used to remove harmful gases such as hydrogen and nitrogen from molten steel and improve the mechanical properties and surface quality ...

-

Customized On Demand Uns G51400 Steel Suitable For Gear And Shaft PartsMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - April 28, 2025 - 704.00 Dollar US$

Customized On Demand Uns G51400 Steel Suitable For Gear And Shaft PartsMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - April 28, 2025 - 704.00 Dollar US$UNS G51400 steel is a commonly used alloy structural steel, which is indeed suitable for manufacturing gear and shaft parts. Performance requirements for gear and shaft parts • Sufficient strength: Gears are subjected to alternating contact stress an...

-

Quality Assurance Astm 5140 Chemical CompositionMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - April 28, 2025 - 702.00 Dollar US$

Quality Assurance Astm 5140 Chemical CompositionMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - April 28, 2025 - 702.00 Dollar US$5140 steel is a medium carbon alloy steel, and its main ASTM 5140 chemical composition is as follows: - **Carbon (C)**: 0.38%-0.43%. Carbon is one of the main elements that determine the strength and hardness of steel. A moderate content can make the...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"