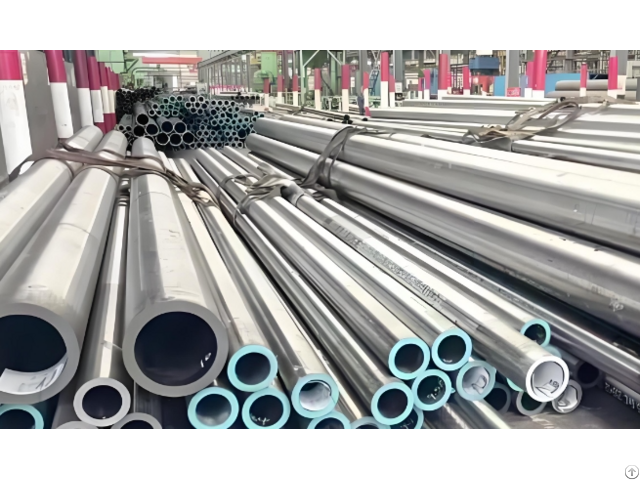

Preheat Treatment Aisi 5140 Steel Pipes Before Welding - China

price: 318.00 Dollar US$

AISI 5140 steel pipes are medium-carbon alloy structural steels (carbon content 0.38%-0.43%, Cr content, the primary alloying element, 0.70%-0.90%).

Their weldability is moderate.

Due to their high carbon equivalent, they are highly susceptible to cold cracking during welding, and the weld zone is prone to the formation of a hardened structure (martensite), resulting in reduced toughness.

Therefore, preheating before welding is a key process step to ensure weld quality, requiring strict control of the preheating temperature, range, heating rate, and holding time.

Preheating Preparation

Surface Cleaning: Remove impurities such as oil, rust, and scale within a 20mm radius on both sides of the welded joint (using a wire brush, sandpaper, or sandblasting is recommended).

This prevents impurities from burning during preheating and creating pores, which could affect temperature uniformity.

Joint Positioning: Ensure that the gap and misalignment of the AISI 5140 steel pipes meet the welding process requirements (e.g., gap 2-4mm, misalignment ≤10% of the wall thickness) to avoid rework after preheating due to joint misalignment.

Temperature Measurement Tool Calibration: Use a contact thermocouple (K-type recommended) or infrared thermometer (accuracy ±5°C).

Calibrate the equipment in advance to ensure accurate temperature readings.

(Infrared thermometers should avoid measuring areas with scale or oil to prevent data deviation).

In summary, the key to preheating AISI 5140 steel pipes before welding is "**precise temperature control, uniform heating, and timely connection**.

" Parameters must be optimized based on actual working conditions, and rigorous process monitoring and documentation must be implemented to ensure that the welded joint quality meets mechanical properties and service requirements.

Company Contact:

- Posted By: Dongguan Songshun Mould Steel Co., Ltd.

- Phone: 076985475596

- Address: 1st Floor, No. 1, Dongda Fourth Street, Shatou Community, Chang'an Town, Dongguan , Guangdong , China

- Email:

- Website: https://songshunsteel.com/

Published date: September 1, 2025

- Business Description: Established in 2009,Songshun Steel supplies a wide range of carbon, alloy and tool steel products, including high speed tool steel, cold work tool steel, hot work tool steel, plastic mould steel, engineering steel and machine structural steel etc.

After more than 10 years development and growing, Songshun Steel becomes one comprehensive special steel factory, stockist and exporter.

Combined with experienced exporting team and professional technical knowledge, Songshun Steel offers both technical advice and support, as well as global professional steel solution and service.

Due to satisfactory reliable quality and professional service, Songshun expands our market worldwide, such as Colombia, Chile, Spain, Turkey, Iran, Vietnam, Malaysia ,UAE, Canada, Brazil, Mexico and so on.

Songshun specialized in Special Steel for almost 20 years.

We can supply mold steel, high speed steel, alloy steel, free cutting steel and etc.

Welcome your contact 24 hours a day!!!

Skype/Whatsapp/We chat: +86-18269260283

Songshun Tiktok: mikizhuo

Songshun Facebook: Songshun Steel

Songshun YouTube: MiKi Zhuo

songshunmoldsteel414 04340

Related listings

-

Improved Astm 5140 Round Bars Hot Working PropertiesMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - September 1, 2025 - 312.00 Dollar US$

Improved Astm 5140 Round Bars Hot Working PropertiesMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - September 1, 2025 - 312.00 Dollar US$To improve the hot working properties of ASTM 5140 round bars, several optimization measures can be taken: 1. Heat Treatment Process Optimization -Annealing: Purpose: Softens the material and improves machinability and formability. Process: Heat the ...

-

Spot Purchase Supply Astm 5140 Material Pickling ProcessMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - September 1, 2025 - 311.00 Dollar US$

Spot Purchase Supply Astm 5140 Material Pickling ProcessMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - September 1, 2025 - 311.00 Dollar US$ASTM 5140 material is a type of alloy structural steel. Its pickling process is designed to remove impurities such as surface scale and rust, thus providing an excellent surface condition for subsequent processing or treatment. 1. Pretreatment: Befor...

-

Excellent Hardenability 5140 Material Rich Spot Resources SupplyMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - September 1, 2025 - 318.00 Dollar US$

Excellent Hardenability 5140 Material Rich Spot Resources SupplyMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - September 1, 2025 - 318.00 Dollar US$5140 is a medium-carbon alloy steel with excellent hardenability, primarily due to its chemical composition and heat treatment. The following are the reasons and specific manifestations of its excellent hardenability: Chemical Composition Chromium (C...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"