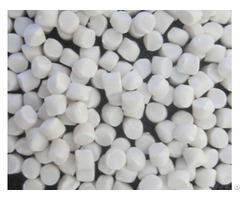

Non Nitrite Vci Resin - Vietnam

price: 298.00 Dollar US$

Non-Nitrite VCI Resin

VCI Resin/Masterbatch (excluding nitrite), is a kind of environmental-friendly product.

It contains no nitrite and heavy metals, fully conforms to SGS, RoHS Reach.

And it does not produce harmful substances in the process of the production of antirust film, and it is green eco-friendly product indeed.

Chi tiết:

VCI Resin/Masterbatch (excluding nitrite), is a kind of environmental-friendly product.

It contains no nitrite and heavy metals, fully conforms to SGS, RoHS Reach.

And it does not produce harmful substances in the process of the production of antirust film, and it is green eco-friendly product indeed.

The safe VCI resin (excluding nitrite) is a basic function masterbatch to produce VCI film, which is made from LDPE, LLDPE and VCI materials.

It is concentrated to the Low density polyethylene masterbatch during in the processing of raw materials mixed .

Its main components are composed of vapor phase corrosion inhibitor and various additives.

VCI masterbatch is mixed according to a certain proportion in LDPE and LLDPE masterbatch, and it need to be fully mixed and dispersed, and then blowing to the film by the machine.

In the processing of production, the heating temperature can not exceed 190 DEG in all areas of blow moulding machine.

Generally, the proportion of mixed vci masterbatch to PE is 1: 50 - However, it should refer to the thickness of the film or application and requested shelf life.

The life of protection anticipated by film containing VCI is 2 years when extruded with ideal processing guideline.

We recommend that an evaluation is made in every single case to confirm that the anticorrosion effect is fulfilling the demands.

It is also recommended to conduct the field tests before regular production.

The characteristics of VCI masterbatch is added into the plastic film, and VCI contained in the film begins to sublimate and volatilize the antirust particles which diffuse and penetrate into the surfaces of the articles for antirust and adhere on them to form a compact protection film with the thickness of monomolecular to avoid the surfaces of the articles for antirust in contact with all factors inducing corrosion, thus the corrosion is effectively prevented.

The vci particles are in good disparity, no crystal point and non-toxic.

Shelf life: 2 years.

The VCI masterbatch series can be increased other functions such as antistastic, smooth, increase transparency, etc.

Applicable Metals:

Steel, copper, brass, bronze, plated metal, zinc and its alloy, chrome and its alloy, cadmium and its alloy, nickel and its alloy, tin and its alloy, and other metal materials and their products Attention matters in application:

1 - The addition ratio of the product is 1: 50

2 - The vci masterbatch and PE material should be mixed evenly.

3 - Attention to the temperature control when blowing VCI film

4 - Attention to the moisture and rainy days.

5 - The VCI film can add the color masterbatch according to the customer’s requirement, however, the color masterbatch which we do not recommend maybe affect the untirust effect.

6 - For the rest of the VCI masterbatch, it need to be sealed promptly, and kept in a cool, dry, and ventilated place, away from sunshine and no contact with sources of ignition and corrosive materials.

Custody and storage:

With sealed package, it shall be kept in a cool, dry, and ventilated place, away from sunshine and no contact with sources of ignition and corrosive materials.

Storage period in the original package is 12 months, opened bags should be closed very tighty after use for further storage.

Remarks:

Since VCI film prevents metals from rusting by means of the continuous and adequate VCI gasified antirust particles volatilized from VCI contained in the film, thin film means less VCI content which may influence the usage effects of the product.

Therefore, on the basis of our practical experience, the recommended standard thickness of the VCI film made from VCI antirust resin shall beu100um (0.10mm, commonly referred to as 10 decimillimeter).

We recommend that only virgin masterbach be used to the production of the VCI film.

If nessary, modifications are made to provide for any additional properties needed such as UV, Anti-Stastic, etc.

Company Contact:

- Posted By: VNFILLER

- Phone: +84856767639

- Address: No 45 Thanh Liet, Thanh Tri, Ha Noi, Ha Noi, Ha Noi, Vietnam

- Email:

- Website: http://filler.com.vn/

Published date: August 29, 2018

- Business Description: VNFILLER was established in 2010 in Vietnam.

We currently own a factory specialized in producing CaCO3 Filler Masterbatch used in the plastics industry, including : factory systems, finished warehouses, raw material warehouses, technology management offices, labs.

With a team of highly qualified and experienced staff and modern technology, VNFILLER always brings high quality products that are stable and meet the needs of customers.

Since the foundation up to now, we have always focused on investing in technology innovation and personnel training; expand the factory, improve productivity, quality; develop domestic and international markets.

Up to now, VNFILLER has become one of the branded enterprises in producing plastic additives products in Vietnam.

Currently, VNFILLER with its products: TICAL 190x: for PP, TICAL 2603: used for film coating BOPP, PP, PE; TICAL 232x: for PE are the products are being offered plentifully in the domestic and exporting markets.

With the aim to meet all strict requirements of customers, VNFILLER wishes to be one of the leading enterprises in Vietnam producing and exporting plastic additives products for the plastics industry.

VNFILLER not only wants to provide plastic additives products with the most stable quality, but also bring the best value-added profit to customers.

PRODUCTION CAPACITY

VNFILLER has a team of engineers and skilled workers, with well-trained management staff, working and satisfying all production and business activities of the Company.

In addition to the experienced and qualified human resources, VNFILLER also has a scientifically layouted plant system and modern machinery lines, operated continuously 3 shifts per day, yielding more than 20, 000 Ton / year and growing in both quantity and quality.

VNFILLER has a modern factory with a total floor area of over 5.000m2, including a system of workshops, warehouses, quality management buildings and operator quarters.

With these strengths, VNFILLER is fully confident to satisfy all requirements of customers in terms of quality, quantity and price of products.

In addition, VNFILLER constantly updates new information on the market and invests in advanced technologies and techniques in the world's manufacturing sector in order to provide customers with products of international standard at competitive prices.

This is the target of striving and also the pride of VNFILLER.

Beside Caco3 powder plentiful resources with the best quality in Vietnam, VNFILLER is also a long-term partner of distributors of other materials and chemicals in Vietnam.

Therefore, VNFILLER always takes the initiative in input materials and get the preferential price from the suppliers.

This is one of the competitive advantages in terms of price and quality of our service.

QUALITY MANAGEMENT

With the motto: product quality is the top priority, the whole of our products before being delivered to the customer must be through a rigorous inspecting process in order to ensure the reputation of the company as well as gives customers peace of mind and satisfaction during the process of using additive products.

VNFILLER with the advantage of having a factory located near the quality, stability and high capacity material source in the world.

The production technology is modern, all the devices are imported from countries with advanced technology in the world in the plastic industry.

Productivity and product quality were superior thanks to the equipment systems are continuously improved, the supply of input materials in the production process are tightly controlled, thus ensuring the quality of products after working out always has high stability.

With the direction of continuous investment in modern production technology, VNFILLER is heading to the clean, environmentally friendly industrial production, and brings manufacturers in plastic industry all the safety additives.

Product research & development is "the survival factor of the business".

Therefore, we have constantly invested in product research and development in the development of quality products, and application of the new additive used in the plastic industry.

Quality control laboratory was also the focus and invested all the test equipment most accurately to ensure the best quality from materials to finished products shipped.

A team of engineers, technicians are always updated information and continuously trained to operate the quality control system to conform to the international standards.

The compositions in the seeds of our additive pellets comply with food safety regulations, no heavy metals, no Phenol, meet REACH standard accord with European regulations.

For further information, please kindly contact us at below address:

VNFILLER

Rep.

Office Address: No.

45, Thanh Liet Str., Thanh Tri, Hanoi, Vietnam

Tel: 84.024.6656.5562 Hotline: 0084.856767639

Email: sales@filler.

com.

vn Website: www.

filler.

com.

vn

Related listings

-

Anti Corosion Vci MasterbatchResins and rosins and other resin derived materials - VNFILLER - Vietnam - August 29, 2018 - contact company for price

Anti Corosion Vci MasterbatchResins and rosins and other resin derived materials - VNFILLER - Vietnam - August 29, 2018 - contact company for priceVCI Resin/Masterbatch, is a special anti-corrosion PE additives, which is used to manufacture anticorrosion film. In addition, this Masterbatch can also be used to produced VCI Bubble Wrap, VCI Foam and other packing materials. Chi tiết: VCI Resin/Ma...

-

Caco3 Filler Masterbatch Producer For Blow FilmResins and rosins and other resin derived materials - VNFILLER - Vietnam - August 29, 2018 - contact company for price

Caco3 Filler Masterbatch Producer For Blow FilmResins and rosins and other resin derived materials - VNFILLER - Vietnam - August 29, 2018 - contact company for priceVnFiller's DLF17 is used in plastic production to reduce cost, increase the heat resistance and durability for the product, increase the flexibility for printing and opacity thus reduce the colour masterbatch and make really big saving for material c...

-

Calcium Carbonate Filler Masterbatch ManuafactuerResins and rosins and other resin derived materials - VNFILLER - Vietnam - August 29, 2018 - contact company for price

Calcium Carbonate Filler Masterbatch ManuafactuerResins and rosins and other resin derived materials - VNFILLER - Vietnam - August 29, 2018 - contact company for priceDLF14 is a polyethylene based master batch containing (75-85%) calcium carbonate. It is grayish white with excellent sisersibility. Chi tiết: Product: FILLER MASTERBATCH DLF14 Product Code: DLF14 Applications: 1. PE Shopping bags & garbage bags, ...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"