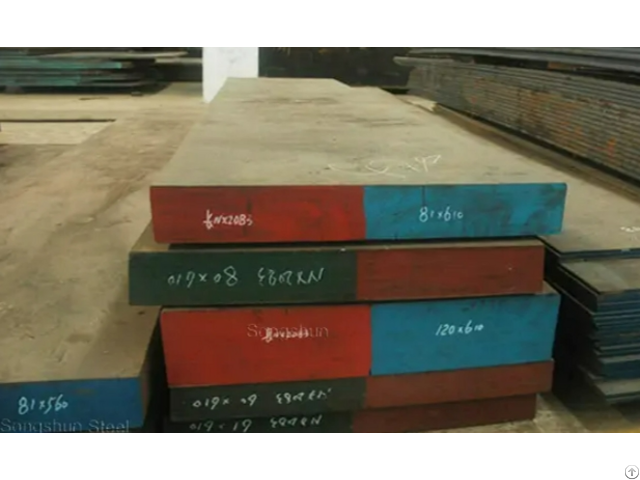

Nak80 Steel Round Bar Sheet Plate Material - China

price: 650.00 Dollar US$

nak80 steel material is a prehardening plastic mold steel.

out of the factory, the hardness can be reached 37-43 hrc.

without s, it has good mirror polish and edm.

after the production of special smelting, it will get high cleanness and stable performance.

nak80 steel has great polishing property, it no needs heat treatment.

perfect machinability and lower surface roughness, the hardness is balance in anywhere.

after the processing of spheroidizzing annealing, its machinability will be better.

add the elements of vanadium and molybdenum in a special way, the wear resistance is up to the next level.

and the toughness also is good, with the great mechanical properties, you do not need to worry about the problem of fracture.

nak80 steel application

the common uses of nak80 steel material as below: mirror polishing mold

tv light filter

cosmetics boxes

office automation equipment

the mold of transparency product of car, camera, computer and more

coining die

shear, blades for woodworking

cold-heading dies

cold extrusion dies nak80 steel round bar sheet plate heat treatment

softening annealing

nak80 steel is heated to 640-720 ºc and then slowly cooled to 500 ºc.

this will yield a maximum brinell hardness of 330 - stress relief

about 550 ºc in the annealed state.

hardening

nak80 steel is hardened at 880-900ºc, followed by oil quenching (in oil, hot water bath or vacuum, the hardness after quenching is 41 hrc.

age hardening

return to the furnace and heat to 550°c±10°c, then keep it at this temperature for 6~8 hours, carry out aging treatment, and then cool naturally to room temperature.

processing methods of nak80

cutting tool

the hardness and cutting resistance of nak80 are higher than others.

so we suggest using the m2 high speed steel (skh9) or superhard alloy p40 - drilling

during the drilling, the bigger size of holes must with lower cutting speed.

our expert engineer team will work with you to find the best steel material and technical help to help you achieve a favorable return on your investment.

after almost 20 years of development and growth, songshun steel becomes one comprehensive special steel factory, stockist and exporter.

the mold steel, tool steel, alloy steel and high speed steel are our main products, they are widely used in military industry, nuclear power, aviation, marine engineering, oil exploration, construction, heavy equipment and so on.

Company Contact:

- Posted By: Dongguan Songshun Mould Steel Co., Ltd.

- Phone: 076985475596

- Address: 1st Floor, No. 1, Dongda Fourth Street, Shatou Community, Chang'an Town, Dongguan , Guangdong , China

- Email:

- Website: https://songshunsteel.com/

Published date: April 29, 2024

- Business Description: Established in 2009,Songshun Steel supplies a wide range of carbon, alloy and tool steel products, including high speed tool steel, cold work tool steel, hot work tool steel, plastic mould steel, engineering steel and machine structural steel etc.

After more than 10 years development and growing, Songshun Steel becomes one comprehensive special steel factory, stockist and exporter.

Combined with experienced exporting team and professional technical knowledge, Songshun Steel offers both technical advice and support, as well as global professional steel solution and service.

Due to satisfactory reliable quality and professional service, Songshun expands our market worldwide, such as Colombia, Chile, Spain, Turkey, Iran, Vietnam, Malaysia ,UAE, Canada, Brazil, Mexico and so on.

Songshun specialized in Special Steel for almost 20 years.

We can supply mold steel, high speed steel, alloy steel, free cutting steel and etc.

Welcome your contact 24 hours a day!!!

Skype/Whatsapp/We chat: +86-18269260283

Songshun Tiktok: mikizhuo

Songshun Facebook: Songshun Steel

Songshun YouTube: MiKi Zhuo

songshunmoldsteel414 04340

Related listings

-

Easy To Process S7 Steel Best Seling PlantMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - April 29, 2024 - 770.00 Dollar US$

Easy To Process S7 Steel Best Seling PlantMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - April 29, 2024 - 770.00 Dollar US$s7 steel is composed of chromium-molybdenum alloy. it is specially designed for steels that require a special combination of high impact resistance and toughness, and is easy to process and heat treat. s7 is a high-quality tool steel with excellent w...

-

Steel Production Technology Inspection ProductsMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - April 29, 2024 - 200.00 Dollar US$

Steel Production Technology Inspection ProductsMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - April 29, 2024 - 200.00 Dollar US$steel production technology the quality and type of steel depends largely on the technology and processing technology of steel production. we are constantly learning, innovating and introducing new technologies to improve product quality and producti...

-

Advanced Technology Songshun Steel Production ProcessMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - April 29, 2024 - 100.00 Dollar US$

Advanced Technology Songshun Steel Production ProcessMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - April 29, 2024 - 100.00 Dollar US$preparation before production according to customer demand, prepare relevant raw materials, formulate steel smelting production technology and process. production process usually, our steel production process mainly includes iron making, steel making...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"