Astm 5120h Steel Plate Die Casting Mold Manufacturing Process - China

price: 811.00 Dollar US$

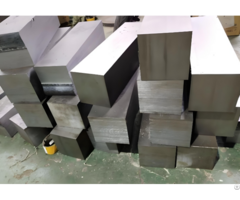

Manufacturing Process of Die Casting Molds with ASTM 5120H Steel Plate Forging

The initial step in manufacturing a die casting mold from ASTM 5120H steel plate is forging.

Forging helps to refine the grain structure of the steel, improve its mechanical properties, and eliminate any internal defects.

The steel is heated to an appropriate temperature and then forged using a press or hammer to the desired shape.

This process also helps to align the grain structure in a way that enhances the steel's strength and toughness.

Machining

After forging, the steel is machined to the precise dimensions and shape required for the die casting mold.

This typically involves turning, milling, drilling, and grinding operations.

High-precision machining techniques are essential to ensure the accuracy of the mold cavity and other critical features.

CNC (Computer Numerical Control) machining is often used in this stage to achieve the desired level of precision and repeatability.

Heat Treatment

Heat treatment is a crucial step in optimizing the properties of ASTM 5120H steel plate for die casting molds.

The typical heat treatment process includes quenching and tempering.

Quenching involves heating the steel to a high temperature and then rapidly cooling it in a quenching medium such as oil or water.

This process hardens the steel by forming martensite.

Tempering is then carried out at a lower temperature to relieve the internal stresses generated during quenching and improve the steel's toughness.

The specific heat treatment parameters depend on the size and shape of the mold component and the desired mechanical properties.

Surface Treatment

To further enhance the performance of the die casting mold, surface treatments may be applied to the ASTM 5120H steel plate.

Common surface treatments include nitriding, chrome plating, and polishing.

Nitriding involves diffusing nitrogen into the surface layer of the steel to form a hard and wear-resistant nitride layer.

Chrome plating provides additional corrosion resistance and a smooth surface finish.

Polishing is used to improve the surface smoothness of the mold cavity, reducing friction and improving the surface quality of the cast parts.

Company Contact:

- Posted By: Dongguan Songshun Mould Steel Co., Ltd.

- Phone: 076985475596

- Address: 1st Floor, No. 1, Dongda Fourth Street, Shatou Community, Chang'an Town, Dongguan , Guangdong , China

- Email:

- Website: https://songshunsteel.com/

Published date: April 14, 2025

- Business Description: Established in 2009,Songshun Steel supplies a wide range of carbon, alloy and tool steel products, including high speed tool steel, cold work tool steel, hot work tool steel, plastic mould steel, engineering steel and machine structural steel etc.

After more than 10 years development and growing, Songshun Steel becomes one comprehensive special steel factory, stockist and exporter.

Combined with experienced exporting team and professional technical knowledge, Songshun Steel offers both technical advice and support, as well as global professional steel solution and service.

Due to satisfactory reliable quality and professional service, Songshun expands our market worldwide, such as Colombia, Chile, Spain, Turkey, Iran, Vietnam, Malaysia ,UAE, Canada, Brazil, Mexico and so on.

Songshun specialized in Special Steel for almost 20 years.

We can supply mold steel, high speed steel, alloy steel, free cutting steel and etc.

Welcome your contact 24 hours a day!!!

Skype/Whatsapp/We chat: +86-18269260283

Songshun Tiktok: mikizhuo

Songshun Facebook: Songshun Steel

Songshun YouTube: MiKi Zhuo

songshunmoldsteel414 04340

Related listings

-

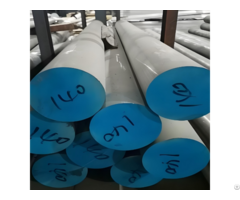

Wholesale Supply Of 5120h Steel Round Bars Finishing Friendly MaterialMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - April 14, 2025 - 787.00 Dollar US$

Wholesale Supply Of 5120h Steel Round Bars Finishing Friendly MaterialMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - April 14, 2025 - 787.00 Dollar US$1. Core advantages of 5120H steel round bars’ finishing friendliness 1. Cutting performance optimization - Annealed hardness ≤187HBW, 15% lower turning resistance than 4120H steel - Chip breaking morphology rating A (ISO 3685 standard), reducing tool...

-

Excellent Wear Resistance W Nr 1 7147 Steel Spot Direct Sales Export MaterialMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - April 14, 2025 - 793.00 Dollar US$

Excellent Wear Resistance W Nr 1 7147 Steel Spot Direct Sales Export MaterialMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - April 14, 2025 - 793.00 Dollar US$Wear resistance extends service life W-Nr. 1.7147 steel's wear resistance is another outstanding advantage. Due to the presence of alloy elements such as chromium, its surface can form a hard and wear-resistant structure after proper heat treatment. ...

-

Quality Assurance Aisi 5120h Steel Manufacturing Automotive Gears Best MaterialMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - April 14, 2025 - 782.00 Dollar US$

Quality Assurance Aisi 5120h Steel Manufacturing Automotive Gears Best MaterialMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - April 14, 2025 - 782.00 Dollar US$AISI 5120H steel is a low-carbon alloy carburizing steel. It has become one of the preferred materials for automotive gears due to its excellent comprehensive performance. The following is its core advantages and application analysis as a gear materi...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"