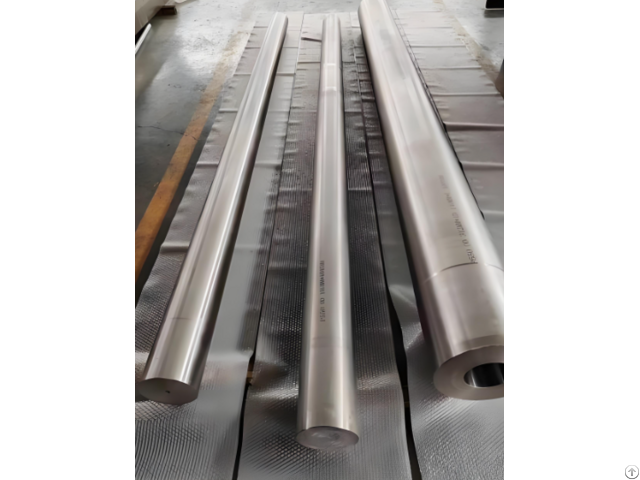

Global Din 51crv4 Alloy Steel Polishing Surface Treatment Technology - China

price: 605.00 Dollar US$

DIN 51CrV4 alloy steel is a commonly used alloy spring steel with excellent mechanical properties (high strength, high toughness, and fatigue resistance).

It is often used in the manufacture of high-stress components such as springs and shafts.

The polishing process requires selecting the appropriate technology based on the material properties and the application (e.g., reducing stress concentration, improving corrosion resistance, or aesthetic requirements).

The details are as follows: Main Polishing Techniques

Depending on the surface roughness requirement (e.g., Ra 0.8μm → Ra 0.02μm), the following steps can be followed:

1 - Rough Polishing (Finishing Stage)

- Tools: Resin-bonded grinding wheel (180-400 grit), wire wheel, or flap wheel.

- Purpose: Remove residual machining marks from pre-treatment and reduce the surface roughness to Ra 0.8-1.6μm.

2 - Intermediate Polishing (Refining Stage)

- Tools: Aluminum oxide or silicon carbide abrasive (600-1200 grit) with a soft cloth or felt wheel.

An oil-based polishing fluid (such as a mixture of engine oil and abrasive) may be added to reduce frictional heat.

- Purpose: Further eliminate scratches, reduce surface roughness to Ra 0.2-0.4μm, and create a preliminary glossy finish.

3 - Fine Polishing (Mirror Finish Stage)

- Tools: Ultra-fine diamond abrasive (1500-8000 grit) or chromium oxide or silica polishing paste (W1-W5 micronized powder) with a wool or suede wheel.

The speed can be increased to 2000-4000 rpm.

- Purpose: Achieve a mirror finish on DIN 51CrV4 alloy steel, achieving a surface roughness of Ra 0.01-0.05μm, meeting requirements for high reflectivity or precise fit.

Through the above technologies, the surface quality of DIN 51CrV4 alloy steel can be effectively improved, taking into account its mechanical properties and reliability.

Songshun Company Website:

https: //songshunsteel.

com/

songshunsteel20240115

Company Contact:

- Posted By: Dongguan Songshun Mould Steel Co., Ltd.

- Phone: 076985475596

- Address: 1st Floor, No. 1, Dongda Fourth Street, Shatou Community, Chang'an Town, Dongguan , Guangdong , China

- Email:

- Website: https://songshunsteel.com/

Published date: October 27, 2025

- Business Description: Established in 2009,Songshun Steel supplies a wide range of carbon, alloy and tool steel products, including high speed tool steel, cold work tool steel, hot work tool steel, plastic mould steel, engineering steel and machine structural steel etc.

After more than 10 years development and growing, Songshun Steel becomes one comprehensive special steel factory, stockist and exporter.

Combined with experienced exporting team and professional technical knowledge, Songshun Steel offers both technical advice and support, as well as global professional steel solution and service.

Due to satisfactory reliable quality and professional service, Songshun expands our market worldwide, such as Colombia, Chile, Spain, Turkey, Iran, Vietnam, Malaysia ,UAE, Canada, Brazil, Mexico and so on.

Songshun specialized in Special Steel for almost 20 years.

We can supply mold steel, high speed steel, alloy steel, free cutting steel and etc.

Welcome your contact 24 hours a day!!!

Skype/Whatsapp/We chat: +86-18269260283

Songshun Tiktok: mikizhuo

Songshun Facebook: Songshun Steel

Songshun YouTube: MiKi Zhuo

songshunmoldsteel414 04340

Related listings

-

High Quality G61500 Spring Steel Precision Processing TechnologyAlloys - Dongguan Songshun Mould Steel Co., Ltd. - China - October 27, 2025 - 603.00 Dollar US$

High Quality G61500 Spring Steel Precision Processing TechnologyAlloys - Dongguan Songshun Mould Steel Co., Ltd. - China - October 27, 2025 - 603.00 Dollar US$G61500 spring steel offers excellent mechanical and processability. Its composition imparts high strength and toughness, good hardenability, and refined grain size, reducing overheating sensitivity. Cold Working Properties G61500 spring steel exhibit...

-

Chromium Carbide Powder With Exclusive Discounts For Long Term CooperationAlloys - Zhuzhou Hastion High-Tech Materials Co.,Ltd. - China - October 23, 2025 - 13.60 Dollar US$

Chromium Carbide Powder With Exclusive Discounts For Long Term CooperationAlloys - Zhuzhou Hastion High-Tech Materials Co.,Ltd. - China - October 23, 2025 - 13.60 Dollar US$Chromium carbide powder has outstanding high-temperature oxidation resistance. Its oxidation rate is low below 900℃ in the air, and the formed oxide film can prevent further oxidation, making it suitable for use in high-temperature working conditions...

-

Ultrafine Titanium Carbide Micro PowderAlloys - Zhuzhou Hastion High-Tech Materials Co.,Ltd. - China - October 23, 2025 - 13.60 Dollar US$

Ultrafine Titanium Carbide Micro PowderAlloys - Zhuzhou Hastion High-Tech Materials Co.,Ltd. - China - October 23, 2025 - 13.60 Dollar US$This powder has excellent electrical and thermal conductivity, with an electrical conductivity of 3×10⁴S/m and a thermal conductivity of 35W/(m·K), and can be used to make conductive ceramics, heating elements, etc. After being compounded with copper...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"