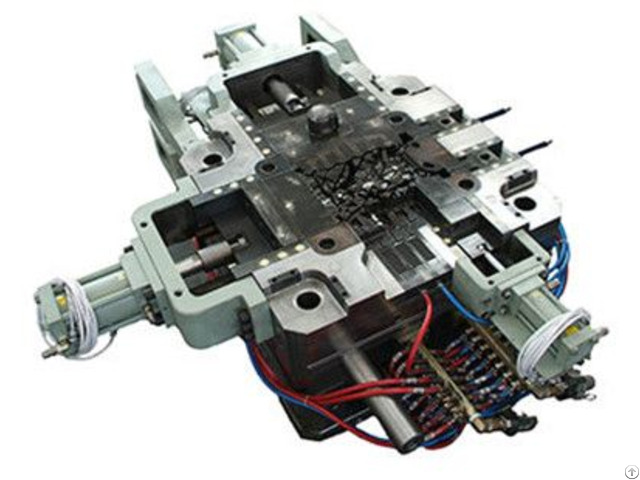

Aluminum Casting Mold Making - China

price: contact company for price

Custom Aluminum die cast mold service Aluminium Die Casting Manufacturers In China Aluminum Casting Mold Making 3D and 2D products drawing from customer, the step of mould flow simulation is necessary.

To find any potential defects during casting.

For example, some parts have A surface and B surface request.

Particularly for nickel finishing die casting parts.

No any air porosity allowances, many of parts will need secondly machining.

Have air bulb occur after machining.

Some parts will have very strict tolerances in same axle.

This time JSCAST CAE software will offer great solution.

in fact all aluminum die casting molds manufactory designer need advanced CAE software to help their job, not only the experiences.

DFM for customer confirm, the step of raw material quality checking is very important, particularly the mold core material checking.

Now material of H13, SKD61, 8407, 1.2344, DH-31 widespread use in Ningbo die casting mold manufactory.

We not only checking the checking the chemical composition and mechanical property.

The material pure standard also very important for die casting tooling.

Any impurity contain in mold core will caused crack problem after thousands injection times, rough grinding, milling, and rough CNC machining before heat treatment.

After heat treatment will take precision grinding and precision machining.

In our pressure die casting mould workshop equipped with high speeding five axle machining center.

EDM is widespread use in pressure die casting tools production.

This EDM machines great advantage reduce machining cost and solved most complicate structure in HPDC dies, the disadvantage will get corrosion problem.

So high standard EDM machines choose is critical.

Remove oxidation material is necessary step after EDM machining.

Aluminum injection tooling cavity polishing.

Roughness of cavity also important for pressure die casting tooling injection times.

Polishing direction should same direction with mold opening.

Perfect mold design is important for mold injection times and superior quality casting components.

Prevent molten aluminum alloy directly erosion corrosion mold cavity.

Over 70% crack problem caused by part of mold over heating

The injection speed and filling velocity control well when casting gate located in thick part

For excellent air venting, the parting line better located the end of casting system

Let air have time escape from mold cavity before moving die and fixed die closed

Good parting line design should think about how to reduce deburr cost

For strict concentricity casting parts, the products same axle should locate in one cavity whatever female cavity or male cavity.

Meet precision request at same time highest possible reduce secondly machining cost.

Aluminium casting company began to produce die cast mold according to the drawings provided by the customer, and through the perfect mold design, our aluminum alloy die casting can better reduce the cost of burrs.

Company Contact:

- Posted By: Ningo Goal Sure Machining Co. ,Ltd

- Phone: 86057483017530

- Address: Dong Qiao Zhen Bai Liang Qiao Cun, Haishu District, Ningbo , Anhui Sheng, China

- Email:

- Website: https://www.gsdiecasting.com/

Published date: April 18, 2021

- Business Description: Ningo goal sure machining co.

,ltd was founded in 2001, located aluminum die casting mold hometown Ningbo.

Year 2007 company total investment 50million yuan, on 30 acre land build up 2000 square meters pressure die casting mold workshop, 3500 square meters pressure aluminum casting products workshop, 600 square meters aluminum die casting tools accessories workshop.

The factory has more than 20 senior technical staff engaged in pressure aluminum die casting industry many years.

we use most advanced simulation software of JSCAST for precision high pressure die casting tooling, strong technical support for your new die casting parts design.

Report including temperature field analysis, solidification analysis, velocity analysis.

Facility including cold chamber die casting machines from 280T-1600T.

all of our die casting machines equipped with automatic assistances, feeding manipulator, spraying manipulator, fetching manipulator, model constant temperature control system.

400T die spotting machine.

CNC precision mold engraving machines, deep hole drilling, five axle high speeding machining center, slow feeding machines, Testing machines including CMM, tensile testing machine, x-ray machine, metallographic analyzer.

Company of LKM, ASSAB, UDDEHOLM, LK, BOHLER hade branch company not far away from us, this is great advantage for us to purchase high quality stand steel for our aluminum die casting molds, and high quality raw material for our custom die casting parts.

The standard pressure die casting molds base from LK is precision and durable.

We offer die casting mold design and technical support for potential customer.

our main business is custom die casting parts service and custom die casting tools service.

Main products including oil pan die casting mold, aluminum die casting housing for auto clutch, auto engine block, aluminum alloy shift fork, aluminum die cast sofa leg, aluminum die casting TV bracket, corrosion resistant light fixtures, casting bathroom light fixtures……

Our website: www.

gsdiecasting.

com

Related listings

-

Die Cast AluminiumMoldings - Ningo Goal Sure Machining Co. ,Ltd - China - April 18, 2021 - contact company for price

Die Cast AluminiumMoldings - Ningo Goal Sure Machining Co. ,Ltd - China - April 18, 2021 - contact company for priceCustom aluminum die cast components service die cast aluminium automobile die casting mould Different components have different technical request, tolerances request, mechanical property request, also with surface request. Like how about salt spray t...

-

Die Casting Mould ManufacturerMoldings - Ningo Goal Sure Machining Co. ,Ltd - China - April 18, 2021 - contact company for price

Die Casting Mould ManufacturerMoldings - Ningo Goal Sure Machining Co. ,Ltd - China - April 18, 2021 - contact company for priceAluminum die cast with powder coating powder coating die casting die casting mould manufacturer Powder coating for aluminum parts not so difficult compare with chrome finishing aluminum die casting parts in many people mind, this is right. But why st...

-

Aluminum Die Cast With Precision MachiningMoldings - Ningo Goal Sure Machining Co. ,Ltd - China - April 18, 2021 - contact company for price

Aluminum Die Cast With Precision MachiningMoldings - Ningo Goal Sure Machining Co. ,Ltd - China - April 18, 2021 - contact company for priceAluminum die cast with precision machining die casting mold manufactory custom pressure aluminum casting Good machining fixture design will provide high efficiency and guaranteed strict tolerances at same time. How many pieces on one machining fixtur...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"