Milk Powder Filling Line General - China

price: contact company for price

Milk Powder Filling Line-General

Hebei Shipu is committed to providing high quality one-stop packaging service for dairy industry customers, including milk powder canning line, bag line and 25 kg package line, and can provide customers with relevant industry consulting and technical support.

Automatic Milk Powder Canning Line

Dairy Canning Line Industry Introduction

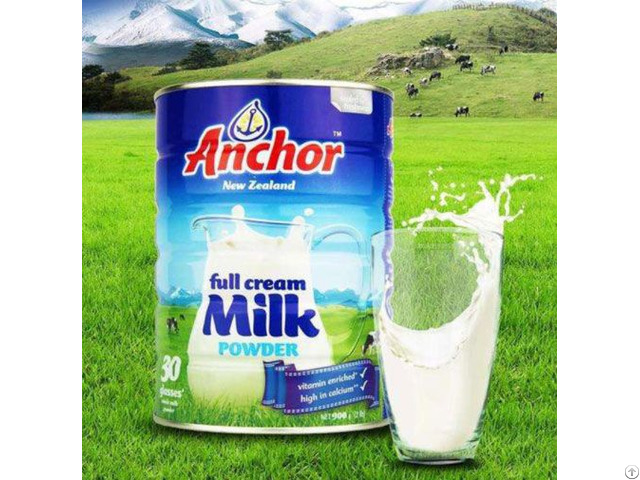

In the dairy industry, the most popular packaging in the world is generally divided into two categories, namely canned packaging (tin can packaging and environment friendly paper can packaging) and bag packaging.

Can packaging is more preferred by the end consumers because of its better sealing and longer shelf life.

The milk powder can production line is specially designed and developed for filling metal tin cans of milk powder.

This milk powder can filling line is suitable for powdered materials such as milk powder, protein powder, cocoa powder, starch, chicken powder, etc.

It has accurate measurement, beautiful sealing and fast packaging.

Our Advantage in Dairy Industry

Are you looking for a fully automatic milk powder filling line? Shipu provides high quality and high precision fully automatic tin cans milk powder canning line.

The milk powder cans can be packaged from 73mm to 189mm in diameter.

During the past 18 years, we have built long term cooperation with world outstanding enterprises, like Fonterra, Nestle, Yili, Mengniu and etc.

Welcome to contact us, we look forward to working with you!

Basic Composition of Milk Powder Can Filling Line

The completed milk powder canning line generally includes de-palletizer, can unscrambling machine, can degaussing machine, can sterilization tunnel, double filler powder filling machine, vacuum seamer, can body cleaning machine, laser printer, plastic lid capping machine, palletizer and etc., which can realize automatic packaging process from the milk powder empty cans to the finished product.

Features of Tin Can Milk Powder Filling Line

1 - The whole machine is made of stainless steel in accordance with food hygiene standards.

2 - Use screw metering to complete metering, filling, etc., suitable for metering different types of powder materials.

3 - Using servo drive system, auger filler fills milk powder with high precision and stable performance.

4 - Open material box, easy to clean.

5 - Fully sealed air resistance glass stainless steel, dust does not leak, and the filling port is equipped with a dust collection device to protect the workshop environment.

6 - Complete all packaging processes such as measuring, feeding, filling, bag making, and printing dates.

The Working Principle of Automatic Milk Powder Canning Filling Line

1 - First place the empty milk powder cans on the rotary bottle unscrambler, which will rotate to bring the cans into the conveyor belt one by one.

2 - The tank cleaning machine will blow the empty tank to remove dust to ensure that there is no impurities in the tank.

3 - Then the empty cans enter the sterilization tunnel, and in the process, the empty cans after UV sterilization and sterilization will be obtained.

4 - The high-precision milk powder filling machine fills the milk powder into the milk powder tank after weighing.

5 - Enter the vacuum nitrogen filling and sealing machine, according to the high-purity canning requirements of milk powder and protein powder, ensure that the residual oxygen rate is less than 2%, automatically cover the can, automatically vacuumize, automatically fill nitrogen, and automatically seal the can without pollution.

6 - After sealing the can, clean the can body.

7 - Since the milk powder filling is carried out from the bottom, the milk powder tank needs to be rotated.

8 - Put on the plastic cover.

9 - Complete the filling of the milk powder can.

Through the processing technology of the vacuum and nitrogen flushing, the residual oxygen can be controlled within 2%, so as to ensure the shelf life of the product to be 2-3 years.

At the same time, the tinplate can packaging also has the characteristics of pressure and moisture resistance, to be suitable for long-distance transportation and long-term storage.

The packaging specifications of canned milk powder can be divided into 400 grams, 900 grams of conventional packaging and 1800 grams and 2500 grams of family promotion packaging.

Milk powder manufacturers can change the production line mold to pack different specifications of product.

Milk powder is a difficult product to fill.

It can exhibit different filling properties depending on formulation, fat content, drying method, granulation and density ratio.

Even for the same product, its characteristics can vary depending on the manufacturing conditions.

We professionally develop and design professional powder filling machines to meet the different needs of users.

Please send us your requirements and we will give you a satisfactory solution for milk powder filling line.

Company Contact:

- Posted By: Hebei Shipu Machinery Technology Co., Ltd.

- Phone: 13903119967

- Address: No. 86, Xisanzhuang Street, Shijiazhuang , Hebei , China

- Email:

- Website: https://www.shiputec.com/

Published date: November 1, 2022

- Business Description: Hebei Shipu Machinery Technology Co., Ltd., a comprehensive enterprise integrating design, manufacturing and after-sale service in Food packaging industry, devotes to providing one-stop service for customers in milk powder, pharmaceutical, health care products, condiments, baby food, margarine, cosmetics, chemical industry and other industries.

In nearly 20 years of history, the company has established strategic cooperative relations with world-renowned enterprises in the industry, such as UNILEVER, P & G, FONTERRA,WILMAR and etc., provided customers with high-quality equipment and perfect technical services and support, which has been highly praised by the customers.

At present, the company has more than 50 professional technicians and employees, over 2000 m2 of professional industry workshop, and has developed a series of “SP” brand high-end packaging equipment, such as Auger Filler, Power Filling Machine, Canning Machine, VFFS and etc.

The equipment have passed CE certification, and meet the GMP certification requirements.

Under the guidance of the national “ONE BELT & ONE ROAD” policy, in order to enhance the international influence of China Intelligent Manufacturing, the company is based on the development and manufacturing of high-end packaging equipment, and cooperation with many international famous brand suppliers, such as: SCHNEIDER, ABB, OMRON, SIEMENS, SEW, SMC, METTLER TOLEDO and etc.

Based on the manufacturing center in China, we have developed regional offices and agents in ETHIOPIA, ANGOLA, MOZAMBIQUE, SOUTH AFRICA and other African regions, which can provide 24-hour fast service for local customers.

The Middle East and Southeast Asia regional offices are also in preparation.

Once you choose SHIPUTEC, then you will get our commitment:

MAKE INVESTMENT MORE SIMPLE!

Related listings

-

Metal ProcessingMachinings - Ningbo Beilun Jointway Leader Machinery Co., Ltd - China - October 26, 2022 - contact company for price

Metal ProcessingMachinings - Ningbo Beilun Jointway Leader Machinery Co., Ltd - China - October 26, 2022 - contact company for priceStamping is mainly classified according to the process, which can be divided into two categories: separation process and forming process. The separation process is also called blanking, and its purpose is to separate the stamping parts from the sheet...

-

New Heavy Duty 3axis Cnc Router Akm1325Machinings - ACCTEK - China - October 23, 2022 - 4700.00 Dollar US$

New Heavy Duty 3axis Cnc Router Akm1325Machinings - ACCTEK - China - October 23, 2022 - 4700.00 Dollar US$AKM1325 is an affordable CNC router, also known as 4x8 CNC router because of its worktable size of 4x8 feet. It is widely used in wood furniture industry and advertising industry. New designed overall sheet metal for all the four sides, looks more co...

-

Oem Plastic Cnc Milling Machining PartsMachinings - Dongguan Richen Precision Manufacture Co., Ltd. - China - October 18, 2022 - 5.99 Dollar US$

Oem Plastic Cnc Milling Machining PartsMachinings - Dongguan Richen Precision Manufacture Co., Ltd. - China - October 18, 2022 - 5.99 Dollar US$Material Capabilities: Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys. Application: Industrial Equipment, Automation, Aerospace, Medical Equipment: 3/4/5 Axis Center Machining Drawing Format: 2D/ (PDF...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"