Cassava Starch Production Line Technology Support - China

price: 360000.00 Dollar US$

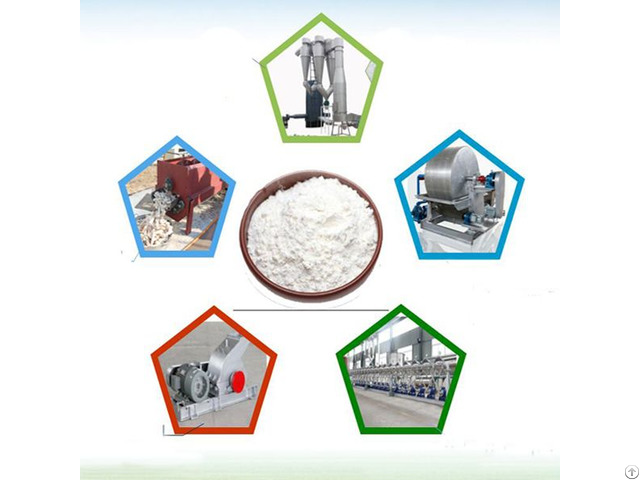

1 - Raw material receiving unit Material receiving unit is the first link of cassava starch processing.

The primary purpose of this unit is the cassava preliminary removing impurity and the smooth storing in inside of raw material storage tank.

2 - Raw material conveying unit Cassava stored in the cassava hopper is conveyed to the large inclination-angle belt conveyor through conveying belt at the bottom of the hopper, and further is conveyed into cleaner to remove impurities by the large inclination-angle belt conveyor, removing sand and other impurities mixed in the materials at harvest time.

3 - De-stoning, cleaning and crushing unit Clean raw materials for cassava processing play an important role, so de-stoning and cleaning unit of pretreatment stage is the most important.

The purpose of this unit is to get rid of sandstone, clay of cassava, and to deposit cleaned cassava in the cassava temporary hopper.

4 - Rasping and pumping unit Rasping unit is the most important link to influence cassava starch extraction rate.

Efficient rasper can release cassava starch particles from cassava cells thoroughly, guaranteeing the combination starch content of cassava residue to the minimum.

Cassava slurry below the rasper is pumped into de-sanding unit with a fiber pump.

The stainless steel rasper with special design is easy to operate.

Concise file clamping system ensures the file working in its best position.

5 - hydro-cyclone and de-sanding unit Cassava slurry got from rasping is pumped into the de-sand cyclone through a fiber pump.

Materials with certain pressure enter into the de-sand cyclone along the tangent, cassava slurry in the hydro-cyclone is rotating with high speed, light starch and cassava residue etc.

overflow from the top of the hydro-cyclone, while heavy sand is discharged from the bottom of the hydro-cyclone.

6 - Centrifugal extraction unit Centrifugal extraction unit is another key units of the whole production line to influence cassava starch extraction rate, good centrifugal screen and process technology can help extract out all the free starch from broken cassava cells.

7 - Cassava residue de-watering unit Cassava residue pumped from the extraction unit proceeds with de-watering by a centrifugal sieve, the working principle is the same as an extraction sieve.

8 - Concentrating and refining unit Concentrating and refining unit is the most important one of the whole production line, starch quality can be guaranteed fully in hydro-cyclone refining unit.

9 - Fine fiber separation unit

Fine fiber separation unit is assorted unit to concentration and refining unit; its main purpose is to reduce working pressure of hydro-cyclone.

10 - Starch de-watering unit

Starch milk with too big moisture content came from hydro-cyclone can’t directly dry, so first starch milk needs de-water to make starch moisture content be about 40%.

11 - Air drying unit Air dryer will further dry the de-watered starch to commodities starch required moisture content.

Company Contact:

- Posted By: Jiaozuo Doing Machanical Equipment Co., Ltd

- Phone: 0086 135 2661 5783

- Address: www.cassavaprocessingmach ine.com Zhengzhou,Henan,China, zhengzhou , Henan province, China

- Email:

Published date: February 27, 2018

- Business Description: Spontaneous research and development the following product:

cassava machine, cassava starch machine, cassva processing machine, cassava starch processing machine, gluten syrup machine from statch

Potato, sweet potato and cassava starch production plant

Glucose syrup & Maltose syrup processing plant

Corn syrup & high fructose processing plant

Air flow clash dyer

Drum rotary dehydration machine .

Related listings

-

Wheat Flour Gluten Making MachineryMachinings - Jiaozuo Doing Machanical Equipment Co., Ltd - China - February 27, 2018 - 8000.00 Dollar US$

Wheat Flour Gluten Making MachineryMachinings - Jiaozuo Doing Machanical Equipment Co., Ltd - China - February 27, 2018 - 8000.00 Dollar US$Brief introduction of wheat gluten making machine This gluten making machine is a new type of food machinery, combine dough mixing and washing, widely used in production of starch and cold noodles etc. Working principles of wheat gluten making machin...

-

Potato And Cassava Starch De Watering Centrifugal Peeler For SaleMachinings - Jiaozuo Doing Machanical Equipment Co., Ltd - China - February 27, 2018 - 10000.00 Dollar US$

Potato And Cassava Starch De Watering Centrifugal Peeler For SaleMachinings - Jiaozuo Doing Machanical Equipment Co., Ltd - China - February 27, 2018 - 10000.00 Dollar US$Potato and cassava starch de-watering centrifugal peeler for sale Introduction of centrifuge peeler Centrifugal Peeler is one of the key processing equipment for starch de-watering which is can continuously work and intermittently filter. It is eithe...

-

Rasper Machine For Grain Flour ProcessingMachinings - Jiaozuo Doing Machanical Equipment Co., Ltd - - February 26, 2018 - 20000.00 Dollar US$

Rasper Machine For Grain Flour ProcessingMachinings - Jiaozuo Doing Machanical Equipment Co., Ltd - - February 26, 2018 - 20000.00 Dollar US$Rasper machine for grain flour processing Uses of rasper machine for grain flour processing Ultra-fine crushing of the organization cells of potato, tapioca, sweet potato, konjak and other tuberous material. Design Features of rasper machine: -Wide s...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"