Vitrified Diamond Grinding Wheels - China

price: 80.00 Dollar US$

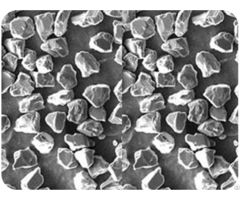

Vitrified diamond grinding wheels are a kind of circular bonded abrasive with through-hole in the center which made of diamond powder and vitrified (ceramic) bond.

It is composed of the diamond layer, transition layer, and matrix.

Vitrified bond compared with resin bond and metal bond

Bond is a kind of material with high bonding ability.

It can bond the diamond grains together and play the role of connecting and fixing.

Bond usually has high strength and good heat resistance, and also has proper hardness.

The surface roughness of the bond is good, and the filler is economical and the grinding efficiency is high.

There are usually 3 kinds of the bond: resin bond, vitrified bond, and metal bond

The main components of resin bond: resin material, which adds some metals and metal oxide powder, conventional abrasive powder, and etc.

The main components of the vitrified bond: some mineral raw materials and vitrified material with the low melting point, and the composition is more and complex.

Its raw materials mainly include 3 parts: Part 1 is plasticity raw materials, such as loess, clay, bentonite, and etc.

Part 2 is barren raw materials, such as fluorite, quartz and etc.

Part 3 is accelerating melting raw materials, such as borax glass, talc, feldspar, and etc.

Applications of the vitrified diamond grinding wheels

Mainly used in wafer (semiconductor silicon and solar wafer), polycrystalline diamond compact (PDC), diamond polycrystalline (PCD), diamond cutting tools, cubic boron nitride (CBN), tungsten steel (cemented carbide), new engineering structural ceramics, crystals, rare earth materials (magnetic materials) and other high hard brittle materials machining.

Superhard material tools include monocrystalline diamond tools, Pcd/Pcbn insert, chemical vapor deposition(CVD) coated tools, and etc.

When grinding monocrystalline diamond tools and PCD/PCBN insert, the grinding efficiency of the vitrified diamond grinding wheels are much higher than that of metal bond and resin bond diamond grinding wheel under the same conditions.

Poor self-sharpening of the metal bond diamond grinding wheel causes low grinding efficiency and great damage to edges of polycrystalline diamond, Cubic Boron Nitride inserts.

Resin bond has good self-sharpening, but the holding of abrasive grains is small, so its processing efficiency is low and mostly used in finish polishing.

There are some small pores that can hold chips and reduce the blockage in the vitrified diamond grinding wheels.

The holding force of bond to the diamond is greater than that of the resin bond, and the grinding efficiency is higher.

Grinding layer organization of vitrified diamond grinding wheels

It mainly consists of diamond abrasive, vitrified bond and pore.

Diamond abrasives: According to the types and grades of diamond, its performance is different and the applied environment is different.

Nowadays, the main types of diamond abrasives in China are MBN, RVD, SMD, DMD, ScD, M-SD, and etc.

RVD type abrasive is mostly used for vitrified bond.

Vitrified bond: It mainly plays the role of connecting and fixing diamond grains and ensure the strength and shape structure of the wheel.

1 Vitrified bond has high strength and good bonding with diamond grains.

It can avoid diamond grains falling off early when grinding and make the grinding wheel fully play the role of grinding.

2 Vitrified diamond wheels have high strength and mostly used in high-speed grinding.

There are often some sudden loads and impact forces.

High strength can avoid danger or machine damage as far as possible.

3 The bond can ensure the abrasives are made into different shapes under certain technology conditions, which is suitable for manufacturing technology of diamond wheel.

4 The bond has high-temperature resistance and chemical stability.

Pore:

The pore is an important component of the vitrified bond diamond grinding wheels.

It also plays a key role in the structure and performance of the wheel.

In the grinding process, the wheel can generate a large amount of heat because of high-speed rotation and movement, and the pores on the wheel are full of grinding fluid and coolant, so they can cool for the wheel.

In addition, there is waste debris in the grinding process, and easily block the contact surface of the wheel and the workpiece, which affect the normal grinding process.

These pores in the wheel can hold the debris, greatly improve the grinding efficiency of tools.

There are 2 main ways to obtain pore in a vitrified bond grinding wheel.

1 Add some pure forming material such as CaCO3, coke breeze, naphthalene, walnut shell granule, and etc.

2 The sintering temperature or the bond is not enough, there will be pores.

But this way can cause the strength of wheel decrease.

Company Contact:

- Posted By: JR diamond tools Co.,Ltd

- Phone: 86-020-31105688

- Address: Building C28, Huachuang Industrial Park, Jinshan Avenue, Shiji Town, Panyu,, Guangzhou , Guangdong , China

- Email:

- Website: http://www.jrdiamondtoolsgroup.com

Published date: September 17, 2019 - Modified date: September 17, 2019

- Business Description: JR Diamond Tools Co., Ltd. was established in 2005, and was known as Henan Runfa Superhard Materials Factory established in 1992 - With more than 20 years of researching and developing on super hard materials, it has developed into one of the leading enterprises of super hard material industry in China.

By our strong R&D teams, strict quality control systems, powerful domestic and foreign sales network, our products have covered stone, ceramic, glass, precious stone, diamond, hard metal, and constantly expanded to the photoelectric high-tech fields such as automotive components, precision mechanical parts, electronic and optical glass.

JR company has got ISO certification from TUV NORD CERT GmbH.

‘Elaborate craftsmanship, firm faith based is our business philosophy, we will continue to create new value for you by right of our outstanding products and perfect services.

Related listings

-

Grooved Ductile 45 Elbow Iron Pipe Couplings And Fittings Wpt SupplierGrinding and polishing and smoothing materials - WEIFANG CHANGSHENG PIPE CO.,LTD - China - October 22, 2018 - contact company for price

Grooved Ductile 45 Elbow Iron Pipe Couplings And Fittings Wpt SupplierGrinding and polishing and smoothing materials - WEIFANG CHANGSHENG PIPE CO.,LTD - China - October 22, 2018 - contact company for price45 ELBOW GROOVED material :ductile iron, Size:inch 1-12 surface treatment:common red painting/Epoxy/Galvanized color:RAL3000 RED, FM Approved and UL Listed, can be used in fire protection, system, feed water, natural gas system and etc. Weifang Chang...

-

Diamond Powder SeriesGrinding and polishing and smoothing materials - Beijing Treeing Material Co., Ltd. - China - August 18, 2018 - 1.00 Dollar US$

Diamond Powder SeriesGrinding and polishing and smoothing materials - Beijing Treeing Material Co., Ltd. - China - August 18, 2018 - 1.00 Dollar US$Treeing provides a comprehensive array of synthetic diamond powder in the micron and sub-micron size range. Micron diamond powders are widely used for the superfinishing of hard materials with demanding specifications for surface quality and dimensio...

-

Polishing Slurry And Compound SeriesGrinding and polishing and smoothing materials - Beijing Treeing Material Co., Ltd. - China - August 18, 2018 - 1.00 Dollar US$

Polishing Slurry And Compound SeriesGrinding and polishing and smoothing materials - Beijing Treeing Material Co., Ltd. - China - August 18, 2018 - 1.00 Dollar US$Treeing supplies varieties of super-precision polishing slurries which are designed for lapping and polishing of precision optical materials and components, super hard work piece such as ceramic and etc. The benefits of the Treeing polishing slurries...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"