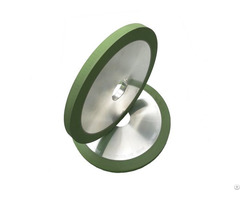

Electroplated Diamond Cbn Wheel - China

price: 80.00 Dollar US$

Electroplated grinding wheels with nickel bonding can achieve high stock removal rates and high-precision profiles on parts being ground.

Depending on the wheel blank design, plating technique, and post-treatment of the single-layer grit structure, many different grinding wheels can be produced using this bond system.

There is no need for dressing during the life of the wheel.

This avoids downtime and eliminates the need for a dressing device.

Electroplated Diamond / CBN Wheel

Electroplated wheels are noted for relatively large grit protrusion and higher abrasive concentration.

This results in very free cutting properties and in high stock removal capacity.

Besides, these tools are noted for:

1 - Allow special shapes and profile tools to be made at short notice.

2 - Cause very little change on wheel shape after used, suitable for precision grinding.

Electroplated grinding wheels are and excellent option when an aggressive amount of stock removal is required.

A single, uniform layer of diamond or cubic-boron-nitride crystal is electroplated to a precision machined steel surface.

The electroplating process gives the most aggressive, open structure of all bonding methods.

This bond type is primarily used in from grinding applications.

*All bonds can be fashioned into any standard or custom shape*

Benefits of Electroplated Wheels:

Aggressive / free cutting bond structure adapts to various spindle speeds

Ability to grind a particular shape or profile

Increased productivity

Improved grind ratios Our diamond plated wheels offer many advantages over other options, including a more aggressive bond, lower initial costs, high performance and long-lasting durability for extended usage.

Our custom enhanced plating guarantees superior performance, and ensures that our plated products are able to maintain both their original shape and dimensions for a longer working life.

The result is a much freer and faster task action and completion.

Electroplated Diamond or Cubic Boron Nitride (CBN) products have a single layer of abrasive held by a tough, durable nickel alloy.

Unlike sintered (metal bond) or resin bond Diamond or CBN products in which the abrasive diamond particles are buried in the bond and held together by a metal or resin binder, electroplated products allow the diamond particles to protrude from the surface for maximum abrasive particle exposure.

Experience freer, faster cutting action with minimum heat generation.

Electroplated Diamond or CBN products are able to retain their original shape and dimensions throughout their working life.

Electroplating allows abrasive particles to protrude from the bond matrix, providing a free, faster cutting action with minimum heat generation.

Electroplated Diamond Tools provide:

Free Cutting Action

Better removal rates and less heat/thermal damage to the part when an aggressive amount of stock removal is required.

Excellent Form Holding Characteristics

Holds tolerance and simple and intricate shape and forms for the entire life of the tool or wheel, from first grind to last.

Maximum Abrasive Particle Exposure

Gives the most aggressive, open structure of all bonding methods.

High Stock/Material Removal Rates

With faster stock removal and increased speed and feeds, lower your long-term cost with the potential reduction or elimination of time associated with setup, dressing, and tool changes.

Reusable

Strip and replate services available with potential savings of 40% over new electroplated products.

Application and Processing Material for Electroplated Wheel

Jig grinding: Mostly used in fined ceramics processing and precision grinding for quartz.

Customized items are also provided to cater your needs.

Common grit size is #80~#325.

Touchscreen Processing: Drilling and chamfering for the glass panel of the smart phone and tablet computer.

We could also combine different grit sizes in the same diamond mounted point.

Grinding for Cutting tools: Normal end-mill grinder and drill grinder go with electroplated wheel.

Carbide can be ground by diamond wheel and High Speed Steel could be ground by CBN wheel.

Precision grinding: Electroplating can produce wheel of different shapes without deforming it.

Therefore, it is suitable for precision grinding or rimming aluminum oxide wheel.

Company Contact:

- Posted By: JR diamond tools Co.,Ltd

- Phone: 86-020-31105688

- Address: Building C28, Huachuang Industrial Park, Jinshan Avenue, Shiji Town, Panyu,, Guangzhou , Guangdong , China

- Email:

- Website: http://www.jrdiamondtoolsgroup.com

Published date: September 17, 2019

- Business Description: JR Diamond Tools Co., Ltd. was established in 2005, and was known as Henan Runfa Superhard Materials Factory established in 1992 - With more than 20 years of researching and developing on super hard materials, it has developed into one of the leading enterprises of super hard material industry in China.

By our strong R&D teams, strict quality control systems, powerful domestic and foreign sales network, our products have covered stone, ceramic, glass, precious stone, diamond, hard metal, and constantly expanded to the photoelectric high-tech fields such as automotive components, precision mechanical parts, electronic and optical glass.

JR company has got ISO certification from TUV NORD CERT GmbH.

‘Elaborate craftsmanship, firm faith based is our business philosophy, we will continue to create new value for you by right of our outstanding products and perfect services.

Related listings

-

Resin Bond Diamond WheelsGrinding and polishing and smoothing materials - JR diamond tools Co.,Ltd - China - September 17, 2019 - 80.00 Dollar US$

Resin Bond Diamond WheelsGrinding and polishing and smoothing materials - JR diamond tools Co.,Ltd - China - September 17, 2019 - 80.00 Dollar US$Resin Bond Diamond Wheels of all types, sizes, shapes and abrasives. Standard grinding wheels can ship from stock. Custom Resin Bond Diamond Wheels and abrasive products can be manufactured promptly. Diamond grinding wheels are designed for wet or dr...

-

Ceramic Bond Diamond Grinding WheelGrinding and polishing and smoothing materials - JR diamond tools Co.,Ltd - China - September 17, 2019 - 80.00 Dollar US$

Ceramic Bond Diamond Grinding WheelGrinding and polishing and smoothing materials - JR diamond tools Co.,Ltd - China - September 17, 2019 - 80.00 Dollar US$Ceramic Bond Diamond Grinding Wheel Surface Grinding Wheel Vitrified Grinding Wheel Most commonly employed in the grinding of PCD and PCBN tools. Coastal Diamond vitrified grinding wheels have enabled polycrystalline tool fabricators to obtain excell...

-

14a1 Resin Bond Diamond And Cbn Grinding WheelGrinding and polishing and smoothing materials - JR diamond tools Co.,Ltd - China - September 17, 2019 - 80.00 Dollar US$

14a1 Resin Bond Diamond And Cbn Grinding WheelGrinding and polishing and smoothing materials - JR diamond tools Co.,Ltd - China - September 17, 2019 - 80.00 Dollar US$Introduction to resin diamond grinding wheel The resin bond diamond wheels are mainly used for grinding tungsten carbide and non-metal materials. Various kinds of dimensions and shapes are available, such as flat shapes, cup shapes and dish shapes, e...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"