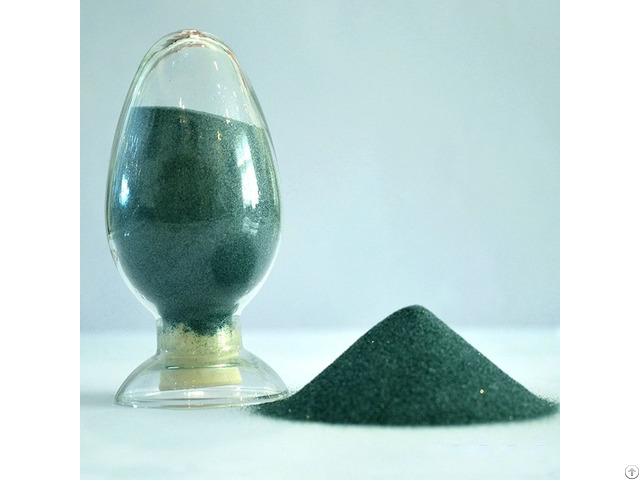

99 Percent Sic Of High Density F36 Grit Green Silicon Carbide Grain Used In Producing Grinding Whee - China

price: 1600.00 Dollar US$

General Silicon Carbide Information

Silicon carbide is composed of tetrahedra of carbon and silicon atoms with strong bonds in the crystal lattice.

This produces a very hard and strong material.

Silicon carbide is not attacked by any acids or alkalis or molten salts up to 800°C.

In air, SiC forms a protective silicon oxide coating at 1200°C and is able to be used up to 1600°C.

The high thermal conductivity coupled with low thermal expansion and high strength give this material exceptional thermal shock resistant qualities.

Macro Grit Specifications

Product Name Green Silicon Carbide

Chemical Composition (%) SiC 99 F.

C 0.2 T.

Fe 0.2

Bulk Density (g/cm3) Min.

Max.

1, 46 1, 54

Grain Size F36

Remark:

● All information and technical data are given as a guide only.

Although every effort has been made to ensure that the information is correct, no warranty is given as to its completeness or accuracy.

Exact specification and sizes will be made strictly according to your rigid requirement.

● All specifications and sizes could be customized.

● For more specifications and detailed information, you are warmly welcome to visit our official website www(dot)greensic(dot)com

Benefits

• Faster cutting and surface smoothing, shorter work cycles, increased production

• Longer cutting life, increased cost-effectiveness, less dust and less clean-up

• Predictable, repeatable results

• Ideal for a variety of applications including grinding, lapping, polishing, and blasting

Applications

• Lapping and Polishing

• Slurry Sawing Quartz

• Brake Shoes for Trains

• Ceramic Coatings

• Buffing Compounds

• Wear Components

• Heating Elements

• Coated Abrasives

• Igniters

• Toner Applications

• Electronic Packaging

• Ceramic Pumps

• Wire-sawing Semiconductor Materials

• Ceramic and Metal Matrix Composites

• Metal Finishing Brushes and Rolls, Etc.

• Granite and Marble Polishing

• Polishing of Precious Stones and Lapidary

• Dispersion in Nickel Matrix for Wear-Resistant Layers, e.g., Cylinders

• Ceramic Seals and Rings

• Wet and Dry Micro-Blasting

• Grinding Media

• Finishing Ball Bearings

• “Scratching” Memory Discs

Company Contact:

- Posted By: Shandong HIJO Precision Abrasives Co., Ltd.

- Phone: 8615962151869

- Address: Caozhuang Industrial Park, Linyi , Shandong Province, China

- Email:

Published date: August 14, 2018

- Business Description: HIJO Abrasives

Shandong HIJO Precision Abrasives Co., Ltd. , (www.

greensic.

com) located in Caozhuang Industrial Park, Linyi City, Shandong Province, China(About 260kms to Qingdao Port, China; about 100kms to Lianyungang Port, China), is one of a leading manufacturer of Green Silicon Carbide both in Macro and Micro grit sizes in China.

We specialized only in producing Green Silicon Carbide Grains/Powders and have decade of years of experience in Green Silicon Carbide crushing, sizing and processing.

We provide high quality specialty Green Silicon Carbide Grains/Powder to meet our customers' rigid specifications.

Our green Silicon Carbide are available in both macro and micro sizing.

If you have special sizing or chemistry requirements, we have the ability to provide both custom particle sizing and custom chemistries as needed.

We also offer other value added solutions to your product needs through custom packaging, shipping, and logistical management.

All of our green Silicon Carbide are certified by our in house lab as well as verified by outside labs.

This ensures the materials meet the specific stringent requirements of each of our customers.

HIJO Abrasives offers short lead times, excellent quality, competitive prices.

We are committed to continual improvement and superior customer service! Contact us today to allow us to serve your needs.

Related listings

-

No Md901 Mini Glass GrinderGrinding and polishing and smoothing materials - Tianjin Mande Industry and Trade Co.,LTD. - China - January 9, 2018 - 37.00 Dollar US$

No Md901 Mini Glass GrinderGrinding and polishing and smoothing materials - Tianjin Mande Industry and Trade Co.,LTD. - China - January 9, 2018 - 37.00 Dollar US$Mini glass grinder is a small size of multifunction grinding machine. Applies to glass, marble, ceramic and other hardness materials for grinding of various kinds of forms: plane, curve, fillet, bevel etc, . Diamond grinder is a new design machine an...

-

Rotating Table Shot Blasting MachineGrinding and polishing and smoothing materials - JX Shot Blasting Machine Co., Ltd. - China - September 23, 2017 - contact company for price

Rotating Table Shot Blasting MachineGrinding and polishing and smoothing materials - JX Shot Blasting Machine Co., Ltd. - China - September 23, 2017 - contact company for priceRotating Table Shot Blasting Machine Supplier JX Offers Rotating Table Shot Blasting Machine, Suitable For Blasting Of Numerous Small Parts. Rotating Table Shot Blasting Machines are for Items that do not lend themselves to being tumbled (tumble belt...

-

Rotary Table Shot BlasterGrinding and polishing and smoothing materials - JX Shot Blasting Machine Co., Ltd. - China - September 23, 2017 - contact company for price

Rotary Table Shot BlasterGrinding and polishing and smoothing materials - JX Shot Blasting Machine Co., Ltd. - China - September 23, 2017 - contact company for priceRotary Table Shot Blasters Maufacturer JX Offers Rotary Table Shot Blasters, For Items That Do Not Lend Themselves To Being Tumbled Or Hung. Rotary Table Shot Blasters are the ideal solution for the cleaning of items of all sizes and weights which do...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"