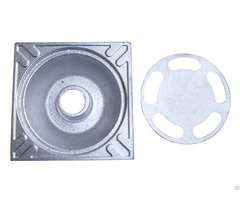

Die Casting Aluminum Heat Sink - China

price: contact company for price

Aluminum Heat Sink

Product Category:

Die-casting aluminum heat sink: common materials ADC10 and ADC12

Extruded aluminum heat sink: common materials AL6061 and AL6063

Stamped aluminum heat sink: common materials 5052, 6061, 6063

Aluminum alloy heat sink

Product Introduce:

Heat sink is a general term for a series of devices used to conduct and release heat.

Heat sink is a heat dissipation structure composed of a base body of the LED heat sink and a plurality of ridges.

Unlike a single slab, the heat sink unit is a U-shaped or V-shaped channel composed of two adjacent ridges and a base.

Heat sink is the most common way to dissipate heat.

Product Feature:

1 - Have a certain heat dissipation area

2 - Have a certain thermal conductivity

3 - Higher thermal emissivity

4 - Light weight

5 - Easy processing

6 - Corrosion-resistant custom Aluminum Alloy Heat Sink Advantage:

1 - Our heat sink is fin type, it is three times higher than traditional heat dissipation efficiency.

2 - Lamp housing is integrated with the heat sink, which avoids the drawback that the traditional lamp housing cannot solve the LED heat dissipation.

3 - Aluminum heat sink has good oxidation and corrosion resistance without adding any additives.

The principle is that once the aluminum encounters oxygen in the air, it will form an oxide film, which is both tough and dense, preventing further corrosion on the bulk material.

1, Aluminum die casting is a process of injection aluminum or aluminum alloy under pressure, which produces parts in high volume at low costs.

2, There are two processes of Aluminum die casting: hot chamber and cold chamber.

3, A complete cycle can vary from one second for small components to minutes for a casting

of large part, making aluminum die casting the fastest technique available for producing precise aluminum & aluminum alloy parts.

4, Any aluminum die casting parts are customized according to the clients' drawing or samples.

More information you can views here Product Description:

Product Name DIN Aluminum Alloy led heat sink

Material Aluminum or Aluminum Alloy 101, Alloy 1070

Standard DIN ANSI ISO JIS GB BA

Tolerance International Standard -ISO 8062

Production Process 1, Sign Drawing (General clients provide the drawing or samples)

2, Opening the Mould

3, Die Casting ( Aluminum or Aluminum Alloys)

4, Precision Machining (Burring, Lathe, Milling, etc)

5, Surface treatment: Polishing, Electroplating, Sandblasting, Anodizing

6, Inspection and Packing

Company Contact:

- Posted By: Botou Junteng Casting Co.,Ltd

- Phone: 15075795793

- Address: Shengli Road, Botou City, Botou , Hebei , China

- Email:

- Website: https://www.aluminumcastingiron.com/

Published date: September 26, 2019

- Business Description: Botou Junteng Casting Co., Ltd. is located in the west of Botou City which covers the area of 30,000 square meters including the production area 15,000 square meters, The fixed assets are 1 million US dollars.

There are 30 workers at present including 8 skilled workers and 2 engineers.

We have passed ISO9001 international quality management system authentication.

We have upright centrifugal molding, horizontal centrifugal molding, metal gravity casting, sand gravity casting, die-casting and polishing equipment and production crafts.

Our products series include iron, aluminum and copper materials.

Our production, examining, measuring and testing equipment is complete and excellent.

The advanced spectrum analysis instrument guarantees the chemical composition of the casting, hardness measuring machine and the metallography examining and pulling force testing machine guarantee the mechanic performance.

We have rich capability of independent research, design, development, production and measuring.

Our main market includes Europe, Middle-East, North Africa, Australia and so on.

WE WILL FOLLOW THE PRINCIPLE OF "SINCERITY BASIC, CUSTOMER THE HIGHEST, OUTSTANDING PURSUIT, AND IMPROVING CONTINUOUSLY" TO OFFER ALL KINDS OF HIGH-QUALITY CASTING PRODUCTS TO DOMESTIC AND INTERNATIONAL CUSTOMERS WHOLEHEARTEDLY.

We hope to cooperate with you sincerely and develop side by side to cast a brilliant future together.

Related listings

-

Aluminum Floor DrainCastings and casting assemblies - Botou Junteng Casting Co.,Ltd - China - September 26, 2019 - contact company for price

Aluminum Floor DrainCastings and casting assemblies - Botou Junteng Casting Co.,Ltd - China - September 26, 2019 - contact company for priceProduct Introduce: Die-casting aluminum Floor Drain is an important interface between the drainage pipe system and the ground, as an important part of the drainage system. Its performance directly affects the quality of air, which is very important f...

-

Die Casting Aluminum Pump ShellCastings and casting assemblies - Botou Junteng Casting Co.,Ltd - China - September 26, 2019 - contact company for price

Die Casting Aluminum Pump ShellCastings and casting assemblies - Botou Junteng Casting Co.,Ltd - China - September 26, 2019 - contact company for priceThe pump housing is die-casted. Die-casting is a metal casting process that uses a mold cavity to apply high pressure to the molten metal. The pump casing is an accessory on the pump body. Product Introduce: The pump shell acts as a support and is co...

-

Die Casting Aluminum PartsCastings and casting assemblies - Botou Junteng Casting Co.,Ltd - China - September 26, 2019 - contact company for price

Die Casting Aluminum PartsCastings and casting assemblies - Botou Junteng Casting Co.,Ltd - China - September 26, 2019 - contact company for priceOEM (Original Equipment Manufacturer) is the trustee's demand and authorization according to the sample manufacturer. Produced according to the manufacturer's specific conditions, all design drawings are manufactured in accordance with the design of ...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"