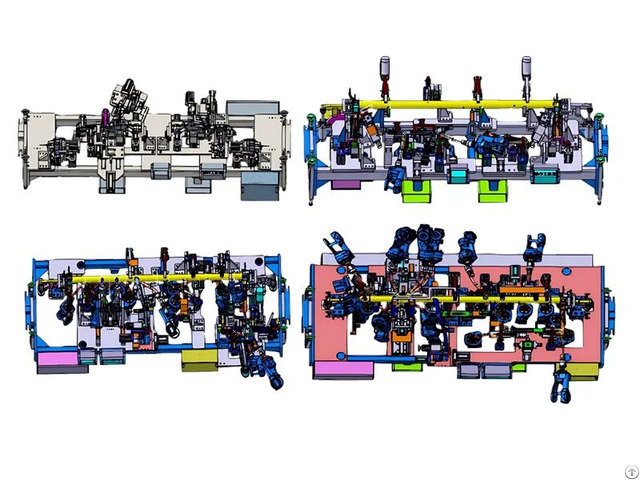

Progressive Die Design - China

price: 1.00 Dollar US$

Shoujia Group was established in 2002 and has been struggling in the automotive market for more than 20 years.

We have taken advantage of the booming development of China's automotive industry and grown from a company located in Shiyan City to a large team consisting of many large factories scattered throughout the country.

Progressive Die Metal Stamping

Progressive metal stamping is one of the most common and cost-effective methods used by manufacturers.

Parts produced using progressive die stamping pass through a variety of stations, each of which performs a specific function, such as embossing, blanking, punching, or embossing.

Depending on the requirements of the part, these functions can be mixed and matched to achieve the desired results.

Advantages of Progressive Die Stamping

Increased production speeds.

Because parts are fed continuously, progressive die stamping can produce more parts at a faster rate.

This makes it particularly well-suited for businesses that require high-volume production.

Reduced scrap waste.

Progressive die stamping uses sheet metal to produce parts, which reduces scrap generation.

The optimized design of progressive dies also helps reduce scrap.

Design freedom.

Progressive die stamping can produce parts in a variety of geometries, from simple to complex.

This provides manufacturers with wider design freedom.

Increased production capacity.

Progressive die stamping can handle high throughput and longer production cycles, allowing manufacturers to produce more parts in less time.

High Repeatability.

Progressive die stamping uses hard, durable dies that allow for high volume production without damaging the dies.

This allows manufacturers to produce high quality parts with optimal repeatability.

Lower cost per part.

Progressive stamping dies reduce cost per part by increasing production speed, repeatability, quick setup and reducing material waste.

Since the process can be easily automated, it reduces labor costs and lowers the risk of workplace injuries.

Achieve tight tolerances.

Progressive stamping allows for the production of large quantities of components with high precision and accuracy, and maintains tight tolerances over long production runs.

Company Contact:

- Posted By: Shoujia Group

- Phone: 13100701526

- Address: No. 11, Xiniu 2nd Street, Changfu Industrial Park, hubei wuhan, wuhan , huann , China

- Email:

- Website: https://www.shoujiagloble.com

Published date: December 25, 2024

- Business Description: Shoujia Group was established in 2002 and has been struggling in the automotive market for more than 20 years.

We have taken advantage of the booming development of China's automotive industry and grown from a company located in Shiyan City to a large team consisting of many large factories scattered throughout the country.

Nowadays, we have over 600 acres of Shoujia Industrial Park, supplying more than 1000 types of products to major domestic vehicle and component manufacturers, with an annual output value of over 500 million yuan.

Our Products:

- Metal Stamping Service

- Progressive Die Design

- Custom Silicone Gaskets

- Cross Car Beam Assembly

- A Carbon Steel Pipe

Related listings

-

Metal Stamping ServiceMetal cutting machinery - Shoujia Group - China - December 25, 2024 - 1.00 Dollar US$

Metal Stamping ServiceMetal cutting machinery - Shoujia Group - China - December 25, 2024 - 1.00 Dollar US$Metal stamping is a manufacturing technique that transforms coil or flat materials into designated shapes. This process includes various molding methods, including drop feed, punching, embossing, and progressive die stamping. The choice of technique ...

-

Zirconia Ceramic Foam Filter For Steel And High AlloyMetal cutting machinery - Hebei CangChen Imp& Exp Trade Co.,Ltd - China - August 12, 2024 - contact company for price

Zirconia Ceramic Foam Filter For Steel And High AlloyMetal cutting machinery - Hebei CangChen Imp& Exp Trade Co.,Ltd - China - August 12, 2024 - contact company for priceZirconia Ceramic Foam Filters are used for filtration of all types of steel like unalloyed, low alloyed, stainless and high-alloyed. Filters are recommended especially for high quality grades of alloys. With their excellent resistance to attack and c...

-

Smokeless Odorless Fiberglass Casting Filter Mesh For AluminaMetal cutting machinery - Hebei CangChen Imp& Exp Trade Co.,Ltd - - August 12, 2024 - contact company for price

Smokeless Odorless Fiberglass Casting Filter Mesh For AluminaMetal cutting machinery - Hebei CangChen Imp& Exp Trade Co.,Ltd - - August 12, 2024 - contact company for priceFiberglass filtration mesh is an ideal filter material for various metal melts. It is woven with special high-twist & high-strength alkali-free fiberglass and special post-treatment. The maximum temperature resistance can reach 900 ℃. Smokeless &...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"