Xh2308 Gantry Machining Center - China

price: contact company for price

CNC Gantry Machining Center

The main performance characteristics:

1 the spindle of the CNC Gantry Machining Center adopts the high precision spindle assembly, the belt type milling head, the main shaft is the servo motor drive.

X, y, Z axis servo control, the direct connect architecture, with automatic lubricating system, machine tools to achieve a rapid motion; X, y, Z three directions to feed with high accuracy high strength ball screw, high feed speed; driving motor through flexible coupling with screw direct coupled, servo servo motor directly deliver power to the high precision ball screw, no backlash to ensure the positioning precision of the machine tool.

2 Taiwan famous brand spindle with high speed and high precision, high rigidity spindle unit, axial and radial load capacity, speed up to 6000rpm; the center of spindle blowing structure, with rapidly in the tool release after cleaning of the spindle cone center of high pressure gas, to ensure the accuracy of tool clamping;

3 - X, y, Z axis servo control, direct coupled structure is adopted in the Taiwan high precision and high intensity of ball screw, screw installation of pre stretching, connecting rigidity, high feed speed; the servo motor directly transferring power to a high precision ball screw, no backlash, ensure the machine tool positioning accuracy.

The Z shaft is provided with a hydraulic balancing device, which ensures.

4 Y, X, Z three direction guide rails, the lead screw all uses the airtight protection, guarantees the lead screw and the guide rail clean, guarantees the machine tool transmission and the movement precision;

5 the outer protection of the machine tool is designed with the ring structure, which is safe and reliable;

6 - Machining center configuration: the Taiwan high quality of 16 or 20 knife bevel knife library, the shortest path tool change, tool change accurately, short time, high efficiency, the test run, in line with the reliability requirements;

7 using the centralized automatic lubrication device, timing, quantitative automatic intermittent lubrication, stable and reliable work;

8 the machine electrical system wiring neatly, the structure is reasonable, the electric box seal is good, is equipped with the heat exchange system, guaranteed the good use environment;

9 - CNC system (FANUC, Mitsubishi, Siemens, wide number) can be selected.

The system has perfect and reliable interlocking, safety protection and fault diagnosis and alarm functions, equipped with RS232 communication interface;

10 the machine is easy to operate, flexible and quick.

More information you can views here Application:

This machine is used in CNC milling, boring, drilling, tapping, processing of steel, cast steel, cast iron etc.

Machine tool accessory head to realize the of all kinds of plate, plate, shell and mould for complex parts in a fixture in complete drilling, milling, boring, reaming, reaming, tapping a variety of processes.

It can be used for small batch spare parts, processing and manufacturing, of complex, high precision parts processing more show its superiority, also can compose the automatic production line for mass production, to ensure the parts of product quality and efficient production.

Product main technical parameters:

Specifications Units XH2308

Table size mm 800x1600

Max.

load working table kg 3000

Gantry width mm 1200

T-type slot numbers / width /space mm 5-22x140

The moving direction of travel of working table mm 1700

The sliding seat moving direction of travel mm 1200

Spindle up and down movement direction travel mm 500

Distance from spindle end to platform mm 110-610

Spindle specification (model / installation diameter) mm BT50-φ155

Spindle speed r/min 6000

Fast moving X.

Y axis mm/min 10000

Fast moving Z axis mm/min 5000

Feed speed (X.Y.Z) mm/min 5-5000

Spindle motor power KW 15

X.Y.Z shaft motor torque N.

m 30/22/22

X.

Y axis positioning accuracy mm 0.025

Z axis positioning accuracy mm 0.018

X.

Y axis repeat positioning accuracy mm 0.012

Z axis repeat positioning accuracy mm 0.010

X/Y axis guide rail Sliding guide

Z axis guide rail Sliding guide

Weight of machine tool T 12

Company Contact:

- Posted By: Tengzhou Luzhong Machine Tool Co., Ltd

- Phone: 0632-5083086

- Address: Luban Avenue ,Tengzhou City ,Zaozhuang City ,Shandong Province ,China, Zaozhuang , Shandong , China

- Email:

- Website: https://www.lzcncmachine.com

Published date: June 27, 2019

- Business Description: Founded in 1992 ,We ,Tengzhou Luzhong Machine Tool Co., Ltd. , is a large enterprises with glorious chievement and long history ,covers an area of 100 thousand square meters, the construction covers area of 25 thousand square meters.

We have been providing all kind of cnc milling machine ,vertical machining center ,lathe machines ,drilling machines and others cnc mechanical equipment, products,to all sectors of the national economy for more than 20 years .

And our machines are very popular overseas ,and they are exported to more than 50 countries and zones ,and our machines are loved and welcomed by customers .

In the deepening of economic reform, in accordance with the requirements of the overall planning, we enhance our traditional manufacturing industry ,so we build the Shandong CNC Machine Tool Production Base in Jiyang city ,Shandong Province .

In this production base ,we produce vertical machining center,cnc lathe,cnc milling ,assembly production line, machine tools and so on ,it will be the world's first-class modern manufacturing enterprises .

In order to strengthen our own technology, research and development advantages ,we ,Tengzhou Luzhong Machine Tool Co.,Ltd ,founded our design company -Luzhong Design Co.,Ltd in 2004 ,which specialize in the design of CNC machine tools .

Our company formed a good win-win relationship with mechanical and electrical companies in provinces, complete sets of companies and foreign agents.

Not only in the country Company formed a mature sales network not only in the country, but also our products are exported to South America, Africa, the Middle East, Southeast Asia and other countries, and are trusted and praised by vast number of users .

Our company focuses on strict and effective management, product quality and service is our eternal pursuit of the theme.

Our company will always be the spirit of "the pursuit of excellence, sincere service" purposes, and strive to provide users with high-quality products and fast, thoughtful after-sales service.

"Regard the quality as life, undertake the heavy responsibility ", with your support, we will get big progress .

Let us join hands to create a better future!

Related listings

-

Xh7125 Vertical Machining CenterIndustrial machine tools - Tengzhou Luzhong Machine Tool Co., Ltd - China - June 27, 2019 - contact company for price

Xh7125 Vertical Machining CenterIndustrial machine tools - Tengzhou Luzhong Machine Tool Co., Ltd - China - June 27, 2019 - contact company for pricemachining centers manufacturing:Tengzhou Luzhong Machine Tool Co., Ltd machining center main technical specifications: Specifica tions Unit XH7125 Table size mm 900×250 X-axis travel mm 450 Y-axis travel mm 260 Z-axis travel mm 380 Distance from spin...

-

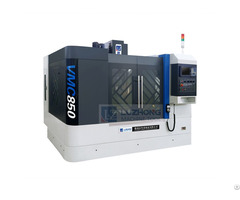

Vmc850 Cnc Vertical Machining CenterIndustrial machine tools - Tengzhou Luzhong Machine Tool Co., Ltd - China - June 27, 2019 - contact company for price

Vmc850 Cnc Vertical Machining CenterIndustrial machine tools - Tengzhou Luzhong Machine Tool Co., Ltd - China - June 27, 2019 - contact company for priceCNC Machining Center Manufacturer China:Tengzhou Luzhong Machine Tool Co., Ltd Features: High quality resin sand Taiwan spindle Taiwan ball screw and locking nut Taiwan pressure cylinder Japanese NSK bearing germany R+W coupling Automatic lubrication...

-

Xk2308 Cnc Gantry Milling MachineIndustrial machine tools - Tengzhou Luzhong Machine Tool Co., Ltd - China - June 27, 2019 - contact company for price

Xk2308 Cnc Gantry Milling MachineIndustrial machine tools - Tengzhou Luzhong Machine Tool Co., Ltd - China - June 27, 2019 - contact company for priceCNC Gantry Milling Machine China, The main performance characteristics: 1 the spindle of the CNC Gantry Machining Center adopts the high precision spindle assembly, the belt type milling head, the main shaft is the servo motor drive. X, y, Z axis ser...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"