Mac G320 Automatic Mold Flux Feeding Machine - China

price: 5000.00 Dollar US$

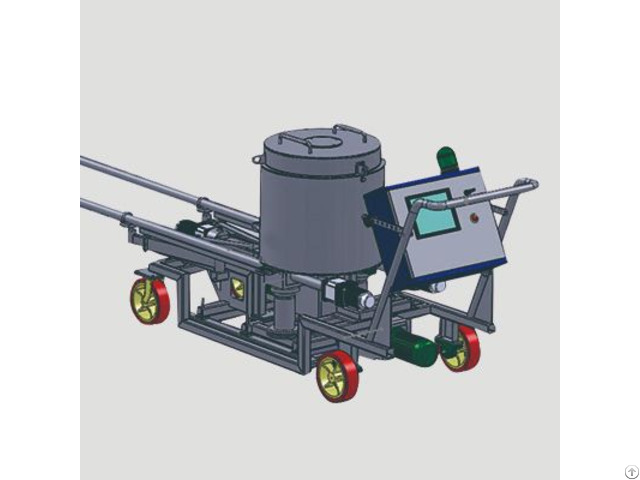

MAC-G320 Automatic Mold Flux Feeding Machine Overview MAC-G320 automatic mold flux feeding system is a new generation product of automatic adding mold flux, which is independently developed by Wuhan CenterRise M&C Engineering Co., Ltd. According to different steel grades, casting speed, vibration and other process parameters, then the system can analyze and calculate the accurate mold flux addition amount through intelligent software.

Then the system sends out signals to control the mold flux addition process and mold flux addition amount, and designs appropriate nozzles and propellers according to the fluidity of molten steel in the mold and the ductility of mold flux.

After the system setting is completed, there is no manual intervention is required.

It completely replaces the whole process of manual addition of mold flux, and realizes the automation of mold flux addition.

The features of the system 1 - The system automatically controls the amount, process and time of adding mold flux according to the process requirements of automatic mold flux addition, so as to maintain the physical state of the mold flux and prevent it from being broken.

2 - The user can match different parameters according to actual needs, so as to change the length of the mold flux feeding time and the amount of mold flux, which can suit for the use of different sections and different casting speeds.

3 - The casting speed signal is used and the amount of adding mold flux can be automatically adjusted according to the casting speed.

The mold flux can be added timely and evenly, which can improve the quality of the billet and reduce labor intensity.

4 - The time is controlled by PLC, no manual intervention is required.

The adjustment is very convenient.

It has manual, automatic, local and remote control modes.

5 - The system has reliable performance and simple structure, and can be adapted to powder and granular mold flux.

6 - It has a special anti-blocking nozzle and backflushing design to overcome the phenomenon of pipeline blockage.

7 - Strong operability, simple and convenient maintenance, and low maintenance cost.

8 - It can maintain the even distribution of the flux layer in the mold.

The composition of the system The system consists of feeding trolley, feeding bucket, swing arm and feeder motor, swing arm transmission device, PLC and control equipment.

1 - The feeding trolley is the support and walking equipment of the mold flux feeder.

The basic equipment of the adding mold flux machine is installed on the feeding trolley.

At the same time, the trolley can easily make the mold flux feeder walk to the working position or the parking position.

2 - The feeding bucket is a device for holding mold flux.

The mold flux is pre-filled in the feeding bucket and is evenly output through the feeder.

The feeding bucket is provided with alarm contact of mold flux level limit.

3 - The swing arm and the feeder motor form a feeding and conveying device.

The mold flux is evenly transmitted to the feed opening at the front end of the swing arm through the screw distributing device controlled by the motor.

Then the mold flux can be used for mold distribution.

4 - PLC and control equipment adjust and control the mold flux feeding speed, operation mode and control mode of the mold flux feeding machine, and realize various control modes and rates.

5 - The swing arm transmission device controls the reciprocating motion of the swing arm according to the size of different molds, so that the mold flux is evenly distributed in the mold.

The technical parameter Mold width: 500-2000mm Mold thickness: 100-500mm Type: screw conveying type mold flux feeding machine Heating method: stirring electric heating Arrangement location: on the pouring platform (with its own wheels to move) Adding capacity: 0.5~7.5L/min, continuously adjustable feeding tube Molding flux storage tank: ~125 L, with material level detection and alarm Control mode: local/remote control, automatic /manual mode Molding flux type: granular flux or powder flux flux adding method: spiral swing adding flux Casting speed interlock: yes Mould size setting: yes Signal transmission: DP/Industrial Ethernet

Company Contact:

- Posted By: Wuhan CenterRise M&C Engineering CO., Ltd.

- Phone: 13995588597

- Address: Building 4, Hengxin Industrial Park, No. 8 Xinhua Avenue, Huangpi District, Wuhan , Hubei , China

- Email:

Published date: September 15, 2022

- Business Description: Wuhan CenterRise M&C Engineering Co., Ltd. is a high-tech enterprise specializing in automation products and engineering.

Our business scope includes the research and development, production and sales of automation systems, devices and various instruments.

We are a comprehensive automation company that designs, implements control systems and provides comprehensive automation systems and process control solutions.

Our company has a high-quality design and R&D team and a professional machining factory, with mature high-tech products and strong technical development and engineering strength, accumulated rich experience in the integration of industrial control systems and information systems.

Our company also cooperates closely with domestic and foreign universities and research institutes.

After years of steady and healthy development, in the fields of industrial automation, building intelligence, and network information, a high-tech enterprise development model has been formed which integrates development and design, system integration, engineering implementation, and complete equipment .

Our company focuses on the research and development of metallurgical measurement and control and automation products, and is committed to the research on key measurement and control of iron and steel metallurgical process automation.

The company's metallurgical measurement and control products cover the entire process of cokemaking, sintering, ironmaking, steelmaking, continuous casting, and steel rolling, and are widely used in major steel mills in China.

In the field of dedicated control, the company develops a series of measurement and control products for related processes, which can independently realize dedicated measurement and control, and can be seamlessly connected with basic automation systems and process automation systems.

It can provide users with comprehensive solutions for system measurement and control and automation.

Related listings

-

Moc K100 Mould Online Oscillation Monitoring SystemIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 14, 2022 - 5000.00 Dollar US$

Moc K100 Mould Online Oscillation Monitoring SystemIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 14, 2022 - 5000.00 Dollar US$MOC-K100 Mould Online Oscillation Monitoring System Overview Mold is the casting billet forming equipment in continuous steel casting, and it is also the core equipment and key technology of continuous casting machine. Its function is to forcibly coo...

-

Zsq T100 Online Surface Quality Inspection System For Casting Billet Eddy CurrentIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 14, 2022 - 5000.00 Dollar US$

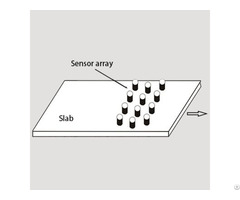

Zsq T100 Online Surface Quality Inspection System For Casting Billet Eddy CurrentIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 14, 2022 - 5000.00 Dollar US$ZSQ-T100 Online Surface Quality Inspection System for Casting Billet (Eddy Current) The principle of the system The ZSQ-T100 online surface quality inspection system for casting billet adopts the principle of eddy current non-destructive testing. Acc...

-

Zsq T200 Online Surface Quality Inspection System For Continuously Cast Product CcdIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 14, 2022 - 5000.00 Dollar US$

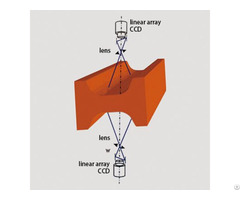

Zsq T200 Online Surface Quality Inspection System For Continuously Cast Product CcdIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 14, 2022 - 5000.00 Dollar US$ZSQ-T200 Online Surface Quality Inspection System for Continuously Cast Product (CCD) Overview The surface quality inspection of high temperature cast product is of great significance to the repair of cast product’s defects and the hot delivery of ho...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"