Lag S100 Ladle Slag Detection System Eddy Current - China

price: 5000.00 Dollar US$

LAG-S100 Ladle Slag Detection System (Eddy Current) Overview The continuous casting ladle slag detection device is used to detect the slag content of the ladle nozzle in the steelmaking continuous casting process, so as to improve the cleanliness of the tundish molten steel and obtain the best yield of the ladle molten steel.

The device adopts the principle of electromagnetic induction detection.

The meaning of slag detection To achieve high output: In order to ensure the cleanliness of molten steel in the ladle, if we detect slag by eyes, we often close the ladle prematurely, so that it will reduce the yield of molten steel.

However, if we use slag detection system, we can detect slag accurately and timely, so that the amount of residual steel is controlled at 1%-2% to achieve high output.

Improve the cleanliness of molten steel: The steelmaking slag gets into the tundish is the main reason that affects the cleanliness of finished steel.

The use of the slag detection system can reduce the amount of steelmaking slag carried into the tundish to a very small amount, and can also reduce the defects on the slab surface at least 80%.

Avoid blockage of the nozzle: The steelmaking slag gets into the tundish is also the main reason for the blockage of the nozzle due to secondary oxidation.

After using the slag detection system, the blockage of the nozzle can be greatly reduced.

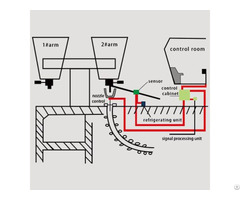

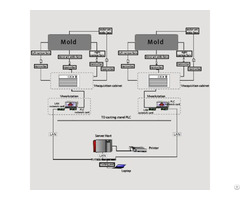

The composition of the system The slag detection system mainly consists of five parts: sensor, preamplifier, signal processing unit, central processing unit and platform control box.

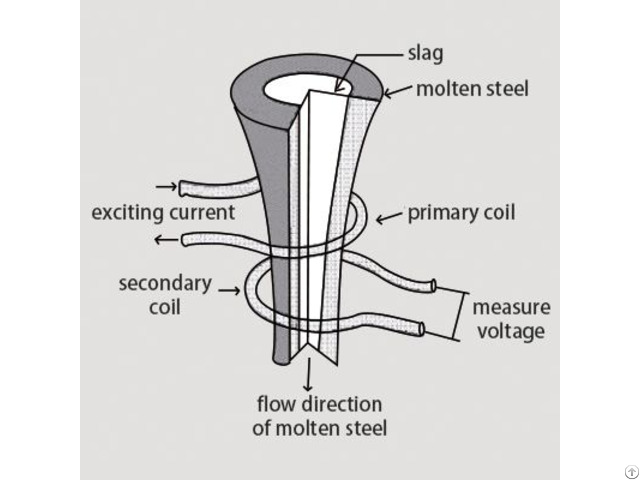

System control flow chart The working principle of the sensor The sensor adopts the principle of electromagnetic induction for signal detection, and its typical structure is two concentric coils.

When the primary coil is supplied with an intermediate frequency excitation current, due to the action of the magnetic field, an eddy current is generated in the steel flow, and the direction of the magnetic field is opposite to the direction of the magnetic field generated by the coil.

Because the conductivity of slag is much lower than that of molten steel at high temperature (about 1/1000), the eddy currents generated in slag are much smaller than those generated in molten steel.

In the process of pouring steel, all the molten steel flows out at the beginning of pouring.

At the later stage of pouring, there will be steelmaking slag mixing out, which reduces the conductivity of the melt and enhances the electromagnetic field.

This signal is measured by the secondary coil.

The technical indexes Sampling time: <10ms System response time: <0.1s Zero point average volatility: <4% System detection value accuracy: <5% (duty ratio) Slag volume alarm setting value: user-defined (recommended to use 20%) Average sensor life: >800 furnaces The working condition Sensor use ambient temperature: <900℃ Operating temperature of secondary instrument: <40℃ Storage and transportation temperature of secondary instrument: -20℃-+70℃ The relative temperature used by the secondary instrument: at 25°C, the maximum is 95%

Company Contact:

- Posted By: Wuhan CenterRise M&C Engineering CO., Ltd.

- Phone: 13995588597

- Address: Building 4, Hengxin Industrial Park, No. 8 Xinhua Avenue, Huangpi District, Wuhan , Hubei , China

- Email:

Published date: September 13, 2022

- Business Description: Wuhan CenterRise M&C Engineering Co., Ltd. is a high-tech enterprise specializing in automation products and engineering.

Our business scope includes the research and development, production and sales of automation systems, devices and various instruments.

We are a comprehensive automation company that designs, implements control systems and provides comprehensive automation systems and process control solutions.

Our company has a high-quality design and R&D team and a professional machining factory, with mature high-tech products and strong technical development and engineering strength, accumulated rich experience in the integration of industrial control systems and information systems.

Our company also cooperates closely with domestic and foreign universities and research institutes.

After years of steady and healthy development, in the fields of industrial automation, building intelligence, and network information, a high-tech enterprise development model has been formed which integrates development and design, system integration, engineering implementation, and complete equipment .

Our company focuses on the research and development of metallurgical measurement and control and automation products, and is committed to the research on key measurement and control of iron and steel metallurgical process automation.

The company's metallurgical measurement and control products cover the entire process of cokemaking, sintering, ironmaking, steelmaking, continuous casting, and steel rolling, and are widely used in major steel mills in China.

In the field of dedicated control, the company develops a series of measurement and control products for related processes, which can independently realize dedicated measurement and control, and can be seamlessly connected with basic automation systems and process automation systems.

It can provide users with comprehensive solutions for system measurement and control and automation.

Related listings

-

Spd V020 Multifunctional Strand Condition MonitorIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 13, 2022 - 5000.00 Dollar US$

Spd V020 Multifunctional Strand Condition MonitorIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 13, 2022 - 5000.00 Dollar US$SPD-V020 Multifunctional Strand Condition Monitor Overview In the production process of the multifunctional strand condition monitor, in order to ensure the quality of the slab, it is necessary to strictly control the performance and various paramete...

-

Lag S200 Ladle Slag Detection System Vibration TypeIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 13, 2022 - 5000.00 Dollar US$

Lag S200 Ladle Slag Detection System Vibration TypeIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 13, 2022 - 5000.00 Dollar US$LAG-S200 Ladle Slag Detection System (Vibration Type) Overview The continuous casting vibration type ladle slag detection device is used to detect the slag content of the ladle nozzle in the steelmaking continuous casting process, so as to improve th...

-

Bps K600 Continuous Casting Mold Breakout SystemIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 13, 2022 - 5000.00 Dollar US$

Bps K600 Continuous Casting Mold Breakout SystemIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 13, 2022 - 5000.00 Dollar US$BPS-K600 Continuous Casting Mold Breakout System Overview: The BPS-K600 continuous casting mould breakout prediction system is developed by Wuhan CenterRise M&C Measuring Co., Ltd. It adopts artificial neural network and combines with traditional...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"