Spindle Automatic Painting Line - USA

price: 100.00 Dollar US$

Spindle automatic painting line, also known as fixed spray gun automatic spraying line, is to fix the spray gun and spray according to the process requirements, if there is a pause or failure in the middle.

This is called the spindle automatic painting line.

So far, we have provided thousands of enterprises with this kind of spindle automatic painting line, we have no accident to stand in the forefront of the industry, electrostatic precipitation, spraying, drying automatic assembly line operation, less employment, suitable for batch continuous production, high output, uniform coating surface; Fully enclosed unmanned spraying operation; The conveyor chain and the track contact point are equipped with bearings to match the precise track, and the operation is light and smooth, stable and without shaking.

Flexibility and great results.

The spingdle automatic painting line is specially designed for the surface coating of plastic shells, and its functions are set by ground rail, automatic conveying, fixed spraying automatic painting, automatic drying and integrated system, and combined with dust-free workshop, spraying to constant temperature control, secondary exhaust gas treatment system, etc., with UV paint paper automatic spraying production process

Advantages of Splindle spraying line:

1 - Ground rail type word conveyor chain is adopted, and the line speed is 0--6m/min through frequency conversion control; 2 - Remove static electricity and dust on the surface of the product through manual ion air gun and automatic ion fan; 3 - Equipped with a preheating dehumidification device before spraying, it can effectively remove the watermark or handprint on the surface of the product; 4 - Three-sided water curtain type fuel injection cabinet is used, equipped with 10HP centrifugal exhaust fan to discharge the exhaust gas; 5 - The spraying area is equipped with a product autotransmission device, so that the product can rotate at high speed when spraying; 6 - The spray gun sprays the product in a fixed form, and each spray gun is responsible for a part of the surface of the product; 7 - The tunnel furnace adopts far-infrared heating tube, the power is 60kw, and the temperature is room temperature -100 degrees Celsius; 8 - The exhaust gas is filtered by spray and activated carbon Automatic spraying production line for workpiece rotation

Suitable for accessories: spraying of plastic workpieces such as mobile phones, power banks, mobile hard drives, cameras, and kettles

Spraying method: multi-joint manipulator, coordinate manipulator, fixed type (can stop spraying, can track spraying)

Baking method: "tunnel roundabout oven with far-infrared heating IR lamp, coating environment: 10, 000 in the coating room, 100, 000 in the workshop, and constant temperature and humidity adjustable

Output: It depends on the tooling method of the workpiece and the baking time of the paint

Process;

UV line: feeding-> manual dust removal - > material preheating - > automatic static dust removal - > automatic spraying 3 (surface painting) - > static setting - > IR - > cooling - > UV curing - > cooling - > blanking

Primer line: feeding - manual dust removal - material preheating - automatic electrostatic dust removal - bottom water spraying - preheating - automatic spraying - static - IR - cooling - blanking

Medium paint: feeding - manual dust removal - material preheating automatic electrostatic dust removal - automatic spraying 2 - static - IR - cooling - blanking

UV line: Feeding - manual dust removal - material preheating - automatic electrostatic dust removal - automatic spraying 3 - static - IR - cooling - UV curing - cooling - blanking

The above is for reference only

Company Contact:

- Phone: 13270465969

- Address: 中国江苏省苏州吴� ��区郭巷镇九盛路33 3号, 苏州 , USA

- Email:

Published date: November 18, 2024

- Business Description: Suzhou Hengjiu Jinye Intelligent Technology Co., Ltd. in China is a scientific and intelligent enterprise specialized in the research and development, design, manufacturing, sales and service of steel plate pretreatment shot blasting and painting equipment.

The company has introduced advanced production technologies and equipment, and owns high-efficiency laser cutting equipment, intelligent numerical control sheet metal equipment, integrated special equipment and advanced stamping, welding and metal processing equipment.

The core parts of products are imported from the United States, Japan, South Korea and Europe, thus ensuring the stability, reliability and advanced nature of product quality.

The company has established a perfect ISO9001-2015 quality standard system and strictly conducts standardized design and planning in accordance with GB (GB/T14295-2015).

The main products are: product research and development, planning, design, production, installation and sales turnkey project general contractor of steel plate sandblasting treatment equipment, steel plate shot blasting treatment equipment, steel plate painting equipment, casting product sandblasting treatment line, heavy workpiece surface treatment equipment, automatic conveying equipment, dust removal equipment and VOC environmental protection equipment! With more than twenty years of industry experience, we can provide customers with professional automatic spraying solutions and rapid technical support.

Standing in the position of customers, we enable customers to invest less funds and generate high benefits.

We have been highly recognized by customers with integrity, strength and quality.

Sincerely welcome new and old customers to come for visit and

Related listings

-

Composite Material MoldManufacturing technologies - Tstar Technology Co.,Ltd. - China - October 16, 2024 - 1000.00 Dollar US$

Composite Material MoldManufacturing technologies - Tstar Technology Co.,Ltd. - China - October 16, 2024 - 1000.00 Dollar US$Composite molds have the advantages of light weight, high strength, corrosion resistance and wear resistance, and are widely used in aerospace, automobile manufacturing and other fields. We provide customized services to ensure that the specific need...

-

Mine Screening MeshManufacturing technologies - Wetter Stainless Steel Wire Mesh Factory - China - October 10, 2024 - contact company for price

Mine Screening MeshManufacturing technologies - Wetter Stainless Steel Wire Mesh Factory - China - October 10, 2024 - contact company for priceMine Screening Mesh, Stainless Steel Strip Mining Screens, Vibrating Screen Mesh Wetter Stainless Steel Wire Mesh Factory is renowned for its comprehensive portfolio of Mine Screening Mesh products, designed to meet the robust demands of the mining i...

-

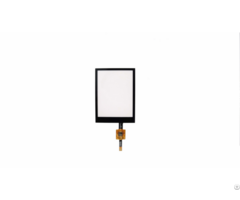

Rxc Gf028126a 1 0Manufacturing technologies - Reshine Display (HK) Technology Co., Limited - China - September 20, 2024 - check with company for price

Rxc Gf028126a 1 0Manufacturing technologies - Reshine Display (HK) Technology Co., Limited - China - September 20, 2024 - check with company for priceProduct name 2.8 inch Capacitive Touch screen Structure Glass+Film Sensor OD 44.2mm*58.6mm Lens OD 49.8mm*68.7mm Thickness of cover glass 0.55mm Driver IC FT6336U Interface I2C interface Surface hardness 6H Touch points Single touch Operating system ...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"