Ceramic Rotary Kiln For Sale - China

price: 23000.00 Dollar US$

As a new type of environmentally friendly materials, ceramic is widely used in petroleum, construction, chemicals, sewage treatment and other industries.

Rotary kiln is the key equipment of ceramic calcining system.

Its performance will directly affect the quality and cost.

For the different characteristics and requirements of the traditional calcining ceramic materials, we developed the new series rotary kiln.

It has the characteristics of even calcining, large capacity, high operation, energy saving, easy operation and maintenance as well as long machine life, and can reduce the equipment operating costs significantly.

Ceramic rotary Kiln features : 1 - For the characteristics and requirements of ceramic calcining process, we make optimize design on kiln head and kiln tail.

It solved the problems of the discharge reverting and dust leakage at kiln tail to have smoothly conveying.

2 - It is micro-negative pressure operation in the cylinder with low dust pollution;

3 - It is even calcination, large capacity and easy to operation and maintenance.

Ceramic rotary Kiln consists of gearing, supporting rollers, catching wheels, cylinder, kiln head, kiln tail sealing and other components, The main structural features are: 1 - There are 2 to 3 fulcrums on kiln.

It is easy to ensure the contact surface of rollers and kiln tires parallel to the cylinder axis during installing;

2 - There are specific gap between the tire and cylinder.

It strengthens the cylinder by confining tires after thermal expansion;

3 - The supports use rolling bearing which simplified bearing structure.

It reduces energy losses during Kiln operation and makes it easier to maintain and repair;

4 - In order to convenient installation and commissioning, there is a kiln slow rotating devices to maintain kiln nonconventional running operation while main transmission system is under overhaul or other abnormal conditions which can occur cylinder bending and deformation during the cooling process.

5 - The kiln uses mechanical or hydraulic catching wheels.

They are high accuracy and reliability.

The ridding rollers and tires are evenly wearing on the entire width direction and are handy adjustment.

;

6 - The kiln head and tail uses elastic flake radial contact sealing.

It can fit the cylinder shape inaccurate and kiln deflection & axial movement.

It has better sealing performance and reliability, longer service life and convenient replacement.

Company Contact:

- Posted By: Henan Zhengzhou Mining Machinery CO.Ltd

- Phone: 8637164685858

- Address: Qiaolou CaizhaiIndustiral Estate, zhengzhou , henna , China

- Email:

- Website: http://www.hnzkmachine.com/

Published date: March 16, 2017

- Business Description: Our company engage in mining equipment industry 60 years, to satisfy requirement in different industry and different place.

Our solution with advanced technology, economy and reasonable ISO quality management system and CE certification, brand certification from EU country to ensure product quality.

To provide comprehensive and systematical technical solution.

Related listings

-

High Quality Ceramic Uv PrinterIndustrial process machinery - SHENZHEN YUEDA PRINTING TECHNOLOGY CO.,LTD - China - March 10, 2017 - 43200.00 Dollar US$

High Quality Ceramic Uv PrinterIndustrial process machinery - SHENZHEN YUEDA PRINTING TECHNOLOGY CO.,LTD - China - March 10, 2017 - 43200.00 Dollar US$Technical features 1. High speed printing:k-onica print heads can realize 60 sq.m/h under 4 pass 2.Ultra wide-format printing: print area up to 3.2 * 1.6 meter, it can print on all types of materials. 3.Three layer printing: special technology of con...

-

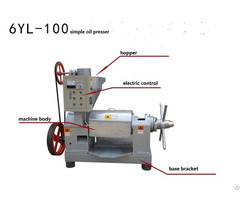

Simple Oil Press MachineIndustrial process machinery - Nanyang QiFeng Machine Co.,Ltd - China - March 1, 2017 - 1620.00 Dollar US$

Simple Oil Press MachineIndustrial process machinery - Nanyang QiFeng Machine Co.,Ltd - China - March 1, 2017 - 1620.00 Dollar US$Model 6YL-100-2 Production Capacity(kgs/h) 100(cold) 160(hot) Main spindle speed 30-35rpm Match Power 11KW+1.1KW Rated Power 380V, 50HZ Automatic Grade Automatic Heating equipment Yes Size 2100*1500*1800mm Weight 1100kgs Package Pallet, wood case Fea...

-

Acrylic Laser Cutting MachineIndustrial process machinery - Unikonex Technologies Co., Ltd. - China - February 28, 2017 - contact company for price

Acrylic Laser Cutting MachineIndustrial process machinery - Unikonex Technologies Co., Ltd. - China - February 28, 2017 - contact company for priceUL-GS series high-precision laser cutting machine is a compact model with Max. processing area 1300x900mm, equipped with the digital control, modular mechanics and software specialized on the cutting of handicraft, electronic and advertising model. I...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"