Stainless Steel Warm Edge Spacer Forming Machine - China

price: 1.00 Dollar US$

1), Price

Model: HG-FS

(9A/12A/14A/16A/18A/20 A/24A)

Price (CNY):2, 160, 000.00

Note: 1 - Including VAT, packaging, shipping and insurance costs 2 - The specific model according to the customer’s choice, one set of equipment can choose one size of warm edge spacer 2), Introduction

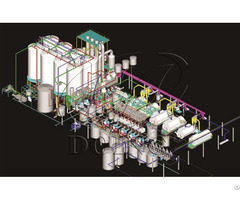

The warm edge spacer forming machine is used for processing complete stainless steel panel, and was developed by the R&D team at Dalian Huagong Innovation Technology Co., Ltd (HGIT).

The machine is the result of three years of research and small batch trial production of ultra-thin stainless steel panels through precision rolling and forming.

After passing a series of rigorous testing and inspection procedures, the equipment has been proven to fully satisfy the demands of constant, continuous processing of warm edge spacers for hollow glass with ultra-thin stainless steel bands.

It also ensures an even and regular geometric form for the warm edge spacer section after forming.

3), Overview of Functions

1, Automatic Uncoiling: 180º dual disc and dual shaft direction conversion, quickly replacing the warm edge spacer band uncoiling mechanism

2, Roller Head Machine: the main component for rolling and forming the ultra-thin stainless steel band (0.12-0.15mm), it comprises over 20 sets of precise rolling wheels, and is driven by a servo motor.

Fully adjustable speed settings, thanks to the chain-driven design, ensure stable and reliable operation of the machine

3, Forming Machine: the forming machine carries out3D forming, and is capable of calibrating and straightening the warm edge spacer after rolling.

Our company holds an independent patent for this device

4, High Frequency Laser Spot Welder: the high frequency pulse laser spot welder is capable of welding the warm edge spacer after rolling, and features a solid welding spot and smooth welding seam

5, Flying cutter: synchronously cuts the warm edge spacer after dynamic formation, at a high speed and to a specific size 4), Technical parameters: Model

HG-FS

Section dimension

15.5mm×6.5mm (for 16A)

Processing speed

0-- 12000mm/min

Welding spots dimension

0.5-1mm

Welding spots distance

1-2mm

Main motor power

5KW

Machine power

30KW (include 1 laser welder)

Voltage

380V

Frequency

50Hz

Overall dimension

15000mmx1000mm (exclusive laser welder)

Floor space

14m×2.5m

Please note:

1 - Each piece of equipment is only capable of processing warm edge spacers of one specific shape and configuration

2 - The processing speed depends on the speed of the laser spot welder, the spot spacing and the quantity of laser welder used.

Company Contact:

- Phone: +86 13390021336

- Address: No.25-18 Yaobei Road, Ganjingzi District,, Dalian , Liaoning , China

- Email:

- Website: https://www.hgcx.cn/en/

Published date: November 3, 2017

- Business Description: Dalian Huagong Innovation Technology Co., Ltd. is a new high-tech enterprise devoting to innovation and research and development established in 2003 with business covering many countries all over the world.

It concentrates on industry, automobile, electric, consumption, energy and construction fields.

The company was listed on NEEQ in Jan.

2014 - It is one of enterprises listed in the first batch after expansion of NEEQ.

Stock Code: 430615 - Stock Abbreviation: Huagong Innovation.

Sealing system, thermal insulation glue injection system and door & window system of the Huagong Innovation HGIT Brand provide innovative and beneficial solutions for clients, thus improve their product quality.

In the meanwhile, the company customizes energy-saving, environment protective, beneficiating and cost-effective system automation lines aiming at customers requirements and serves customers all over the world with professional technology.

The company values combination of production, teaching and researching.

It not only has scientific research and development projects aiming at future development with domestic first-class schools, but also has close strategic cooperation relation with many international transnational corporations.

As a strategic partner of the Dow Chemical – a world 500 top in polyurethane thermal insulation project, the company and HANs Chemical (Dalian) Co., Ltd. – a wholly-owned subsidiary of the company jointly provide systemic solutions for building heat preservation and energy saving.

The Huagong Innovation will persistently provide comprehensive support for customers with innovative technology, excellent solution and superior service.

Related listings

-

Cassava Peeling And Washing MachineManufacturing technologies - Jiaozuo Doing Machanical Equipment Co., Ltd - China - October 30, 2017 - 8000.00 Dollar US$

Cassava Peeling And Washing MachineManufacturing technologies - Jiaozuo Doing Machanical Equipment Co., Ltd - China - October 30, 2017 - 8000.00 Dollar US$Application of cassava peeling and washing machine: used as the pre cleaning section machine to remove 2-3mm inner skin of cassava for the following cassava flour making line Hot sale cassava peeling machine l cassava peeler for cassava flour process...

-

Liquid Glucose Syrup Manufacturing MachineryManufacturing technologies - Jiaozuo Doing Machanical Equipment Co., Ltd - China - October 30, 2017 - 803000.00 Dollar US$

Liquid Glucose Syrup Manufacturing MachineryManufacturing technologies - Jiaozuo Doing Machanical Equipment Co., Ltd - China - October 30, 2017 - 803000.00 Dollar US$Description of liquid glucose syrup industrial machinery: (1) Starch milk adjustment: Dipped rice is pumped to crashing stage, sending to rice storage after de-stone, de-iron and milling. (2) Liquefaction section : Then the material is sent to the fl...

-

Starch Glucose Production LineManufacturing technologies - Jiaozuo Doing Machanical Equipment Co., Ltd - China - October 30, 2017 - 1600000.00 Dollar US$

Starch Glucose Production LineManufacturing technologies - Jiaozuo Doing Machanical Equipment Co., Ltd - China - October 30, 2017 - 1600000.00 Dollar US$Starch glucose production line All kinds of starch sugar will be got by corn starch hydrolysis with acid or enzyme. The liquid products are maltose, glucose syrup, fructose syrup; The description of new technology of starch glucose production line: 1...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"