Automatic Garri Processing Machinery In Nigeria - China

price: 12000.00 Dollar US$

2017 Automatic garri processing machinery In Nigeria Cassava have been used as a source of raw material for high-quality starch and flour for many years.

In addition to product quality, the consumption of fresh water and energy are now playing an ever more important role in cassava starch, casssava flour, garri procesing plant factories.

So we developed process lines which also convince users from these economic points of view.

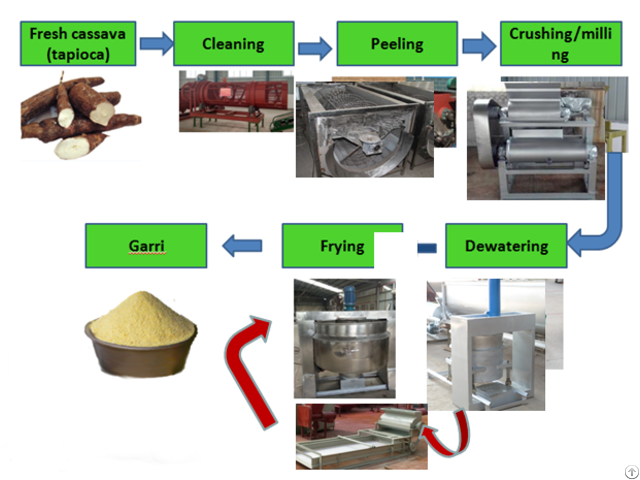

Here is the process of Garri processing plant | garri processing machine

1 - Sorting: After harvest, some roots may be damaged or rotten.

These are sorted to select the wholesome roots for processing; only healthy roots (without rot or other damage) should be processed.

2 - Peeling and washing: Freshly harvested cassava roots are covered with soil and dirt and.

The roots are peeled to remove the outer brown skin and inner thick cream layer and washed to remove stains and dirt.

The water source should be checked regularly to ensure it is not dirty or contaminated.

3 - Grating: As part of the process to remove the cyanide and make the root safe to eat, the peeled cassava are grated into a mash or pulp.

Mechanized graters are needed to produce a sufficient quantity of cassava mash to meet market demands and standards.

4 - De- watering and fermenting: This completes the process of removing cyanide from the cassava mash.

The water content in the mash is reduced using hydraulic press.

The bags are then left to drain and ferment for a few days.

5 - Granulating: The cake is mechanically reduced in size to produce fine granules of greater surface area – known as grits.

6 - Roasting: The grits are then roasted or fryed in a hot frying tray or pan to form the final dry and crispy product.

Gari is normally white or cream, but will be yellow when made from yellow cassava roots or when fried with palm oil.

It is important to make sure the taste and smell is acceptable to local consumers.

Yellow cassava roots and palm oil are rich in vitamin A and therefore make nutritious gari.

The roasted gari are spread on a raised platform in the open air to cool and dry.

7 - Sieving: The Gari is sieved to separate coarse particles, with a standard size sieve to produce fine granules.

A grinder is used to break the large granules into smaller ones.

8 - Packaging: The gari are weighed and then packed for marketing.

Garri is dry, crispy, creamy-white and granular.

It is estimated that 70% of the cassava produced in Nigeria is processed into gari.

As a result, gari is the most commonly traded cassava product.

The gari prices, therefore, are a reliable indication of the demand and supply of cassava.

Other relevant processed cassava foods in the traditional (food) market include fufu, lafun and abacha.

Company Contact:

- Posted By: Jiaozuo Doing Machanical Equipment Co., Ltd

- Phone: 0086 135 2661 5783

- Address: www.cassavaprocessingmach ine.com Zhengzhou,Henan,China, zhengzhou , Henan province, China

- Email:

Published date: August 31, 2017

- Business Description: Spontaneous research and development the following product:

cassava machine, cassava starch machine, cassva processing machine, cassava starch processing machine, gluten syrup machine from statch

Potato, sweet potato and cassava starch production plant

Glucose syrup & Maltose syrup processing plant

Corn syrup & high fructose processing plant

Air flow clash dyer

Drum rotary dehydration machine .

Related listings

-

Potato Starch Processing EquipmentManufacturing technologies - Jiaozuo Doing Machanical Equipment Co., Ltd - China - August 31, 2017 - 126000.00 Dollar US$

Potato Starch Processing EquipmentManufacturing technologies - Jiaozuo Doing Machanical Equipment Co., Ltd - China - August 31, 2017 - 126000.00 Dollar US$The potato starch production process of potato starch processing equipment include seveal steps : potato cleaning and washing, potato wet milling, potato starch extraction, starch milk refining, dewatering of refined starch milk and starch drying. Th...

-

What Is The Main Process Making GarriManufacturing technologies - Jiaozuo Doing Machanical Equipment Co., Ltd - China - August 21, 2017 - 12600.00 Dollar US$

What Is The Main Process Making GarriManufacturing technologies - Jiaozuo Doing Machanical Equipment Co., Ltd - China - August 21, 2017 - 12600.00 Dollar US$What is the main process making garri? What is the main process making garri? Garri is traditionally made at home in Africa. It is increasingly becoming common to produce garri at commercial level using mechanised means. Made from cassava, the tubers...

-

How To Process Garri From CassavaManufacturing technologies - Jiaozuo Doing Machanical Equipment Co., Ltd - China - August 21, 2017 - 12000.00 Dollar US$

How To Process Garri From CassavaManufacturing technologies - Jiaozuo Doing Machanical Equipment Co., Ltd - China - August 21, 2017 - 12000.00 Dollar US$How to process garri from cassava? Gari is a partially gelatinized (by toasting), free-flowing granular flour with a slightly fermented flavor and sour taste. It is consumed either soaked in cold water or stirred in boiling water to make a stiff past...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"